Wastewater treatment is a critical component of modern environmental protection, and the Modified Ludzack-Ettinger (MLE) process has emerged as a leading method for effective nutrient removal.

As concerns about water pollution and environmental sustainability continue to grow, understanding the MLE process is essential for those involved in wastewater treatment. Recent studies have highlighted the MLE process as a widely used and effective method for removing nutrients from wastewater.

The importance of efficient nutrient removal cannot be overstated, as it directly impacts the quality of water released back into the environment. This guide will provide an overview of the MLE process and its significance in wastewater treatment.

Key Takeaways

- Efficient nutrient removal is crucial for environmental protection.

- The MLE process is a widely used method for wastewater treatment.

- Understanding the MLE process is essential for effective wastewater management.

- The MLE process directly impacts water quality.

- Recent studies have highlighted the effectiveness of the MLE process.

Understanding Wastewater Treatment Fundamentals

As the world grapples with water pollution, understanding wastewater treatment fundamentals becomes increasingly important. Wastewater treatment is a complex process that involves several stages, including physical, chemical, and biological treatments.

The Importance of Nitrogen Removal in Wastewater

Nitrogen removal is a crucial aspect of wastewater treatment due to its impact on eutrophication and aquatic life. Excess nitrogen in water bodies can lead to the proliferation of algae, depleting oxygen and causing the death of aquatic organisms. Effective nitrogen removal processes are essential to mitigate these effects.

Evolution of Biological Nutrient Removal Processes

The evolution of biological nutrient removal processes has been driven by the need for more efficient and effective wastewater treatment methods. Over the years, various processes have been developed, including the Modified Ludzack-Ettinger (MLE) process, which is known for its efficiency in nitrogen removal.

Environmental and Regulatory Drivers

Environmental and regulatory drivers play a significant role in shaping wastewater treatment processes. Stricter regulations and growing environmental concerns have led to the development of more advanced treatment technologies, including biological nutrient removal processes. These drivers have pushed the industry towards more sustainable and environmentally friendly practices.

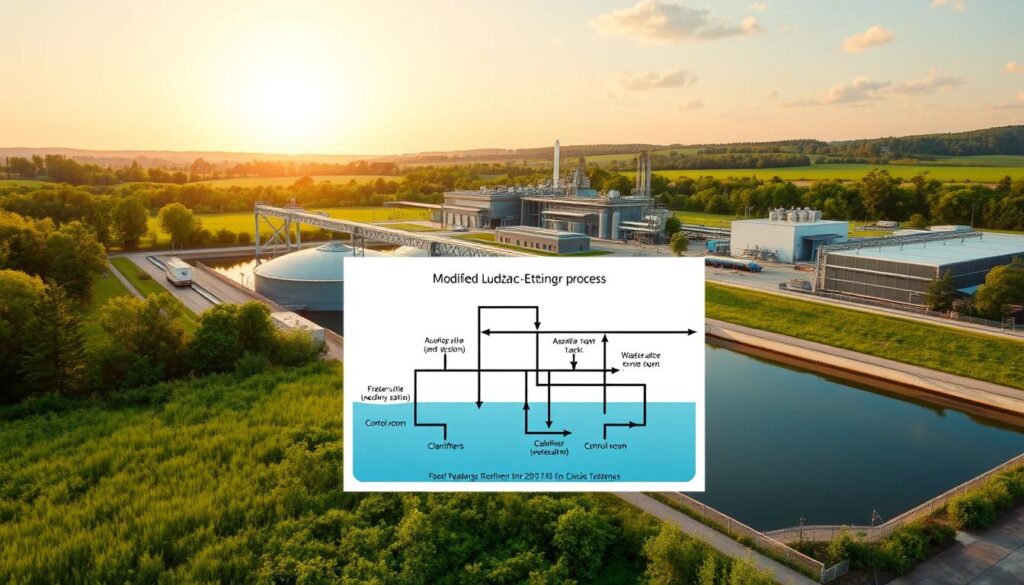

The Modified Ludzack-Ettinger Process Explained

Understanding the Modified Ludzack-Ettinger process is essential for effective nitrogen removal in wastewater treatment. This process is a variation of the conventional activated sludge process, designed to enhance biological nutrient removal (BNR).

Definition and Core Principles

The Modified Ludzack-Ettinger (MLE) process is characterized by its use of an anoxic zone followed by an aerobic zone, facilitating both denitrification and nitrification. The core principle revolves around creating an environment that fosters the growth of microorganisms capable of removing nitrogenous compounds from wastewater.

Historical Development of the MLE Process

The MLE process was developed as an improvement over earlier wastewater treatment technologies, focusing on enhancing nitrogen removal efficiency. It evolved from the need to address environmental concerns related to nitrogen pollution in water bodies.

Key Objectives in Wastewater Treatment

The primary objectives of the MLE process include:

- Efficient removal of nitrogenous compounds

- Reduction of environmental impact through minimized nitrogen discharge

- Compliance with regulatory standards for wastewater treatment

By achieving these objectives, the MLE process contributes significantly to protecting water quality and promoting sustainable wastewater management practices.

How the MLE Process Works

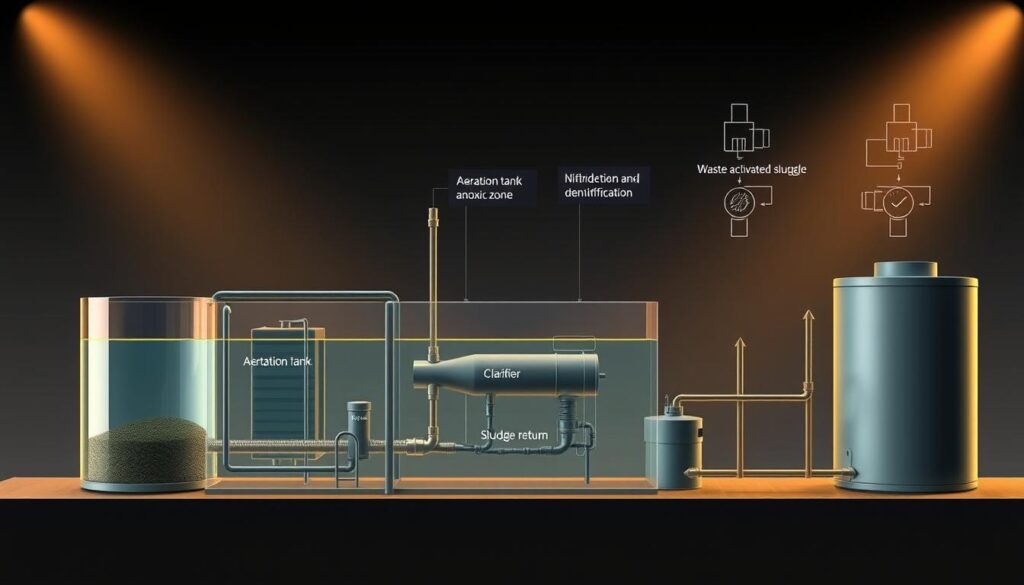

At the heart of the MLE process lies a complex interplay between anoxic and aerobic zones, which are crucial for its effectiveness in wastewater treatment.

The Two-Stage Biological Process

The MLE process operates on a two-stage biological treatment principle, combining anoxic and aerobic conditions to facilitate both denitrification and nitrification. This dual-stage approach allows for efficient removal of nitrogenous compounds from wastewater.

The process begins in the anoxic zone, where denitrifying bacteria convert nitrates into nitrogen gas, thus reducing the nitrogen content in the wastewater.

Anoxic and Aerobic Zones Explained

In the MLE process, the anoxic zone is devoid of oxygen, creating an environment conducive to denitrification. Here, microorganisms utilize the oxygen from nitrates for their metabolic processes, releasing nitrogen gas as a byproduct.

The aerobic zone, on the other hand, is where nitrification occurs. Aerobic conditions enable nitrifying bacteria to convert ammonia into nitrates, a critical step in the nitrogen removal process.

Internal Recycle Mechanisms

Internal recycle mechanisms play a vital role in the MLE process, ensuring that the treated wastewater meets the required standards.

Nitrate Recirculation Fundamentals

Nitrate recirculation involves transferring nitrate-rich mixed liquor from the aerobic zone back to the anoxic zone. This recirculation is essential for maintaining a consistent denitrification process.

Optimizing Recycle Ratios

The efficiency of the MLE process is significantly influenced by the recycle ratio. Optimizing this ratio is crucial for achieving the desired nitrogen removal rates while minimizing operational costs.

By carefully adjusting the recycle ratio, treatment plants can enhance the overall performance of the MLE process, ensuring compliance with environmental regulations.

Components of a Modified Ludzack-Ettinger System

The MLE process relies on a combination of physical infrastructure and biological components to remove nitrogen from wastewater.

Physical Infrastructure Requirements

The physical infrastructure of an MLE system includes reactor tanks, aeration equipment, and internal recycle streams. The reactor tanks are designed to provide sufficient retention time for the biological processes to occur. Aeration equipment is crucial for supplying oxygen to the aerobic zones, while internal recycle streams facilitate the transfer of mixed liquor between the anoxic and aerobic zones.

Biological Components and Microorganisms

The biological components of an MLE system are primarily activated sludge microorganisms that are responsible for nitrogen removal through nitrification and denitrification processes. These microorganisms require a balanced environment with adequate carbon sources, nutrients, and suitable operating conditions to function effectively.

Control Systems and Monitoring Equipment

Effective control and monitoring are essential for the stable operation of an MLE system. This includes online sensors and analyzers that continuously monitor parameters such as dissolved oxygen, pH, and nitrogen levels.

Online Sensors and Analyzers

Online sensors and analyzers provide real-time data that enable operators to make informed decisions and adjust operating conditions as needed. These instruments are critical for maintaining optimal process performance.

SCADA Integration

Many modern MLE systems are integrated with SCADA (Supervisory Control and Data Acquisition) systems that allow for centralized monitoring and control. SCADA systems enable operators to monitor the process from a single location, receive alarms, and make adjustments to maintain optimal operating conditions.

The Biochemistry Behind MLE

Understanding the biochemistry behind the MLE process is essential for optimizing wastewater treatment operations. The MLE process relies on biological treatment mechanisms to remove nitrogen and other pollutants from wastewater.

The process involves two critical biochemical processes: nitrification and denitrification. These processes work in tandem to convert nitrogenous compounds into harmless nitrogen gas.

Nitrification Process in Detail

Nitrification is the process by which ammonia-oxidizing bacteria convert ammonia into nitrite, which is then further oxidized to nitrate by nitrite-oxidizing bacteria. This process occurs in the aerobic zone of the MLE process.

Denitrification Mechanisms

denitrifying bacteria convert nitrate into nitrogen gas. This process occurs in the anoxic zone of the MLE process and requires a carbon source to drive the reaction.

Carbon Source Requirements

The MLE process requires a sufficient carbon source to support denitrification. The carbon source is typically provided in the form of organic matter, which is readily available in the wastewater.

Microbial Communities and Their Roles

The MLE process relies on a diverse range of microbial communities to achieve efficient wastewater treatment. These microorganisms play critical roles in nitrification, denitrification, and other biochemical processes.

Advantages of the Modified Ludzack-Ettinger Process

The Modified Ludzack-Ettinger (MLE) process has emerged as a highly effective method for wastewater treatment, offering several key advantages. This process is particularly noted for its efficiency in removing nitrogen from wastewater, a critical aspect of preventing environmental pollution.

Efficiency in Nitrogen Removal

The MLE process is highly efficient in nitrogen removal due to its two-stage biological process, which includes both anoxic and aerobic zones. This configuration allows for effective nitrification and denitrification, resulting in significant reductions in nitrogenous compounds.

Energy and Resource Conservation

One of the significant advantages of the MLE process is its ability to conserve energy and resources. By optimizing the biological processes, the need for excessive aeration is reduced, leading to lower energy consumption. Moreover, the process can be designed to utilize existing infrastructure, reducing the need for new capital expenditures.

Operational Flexibility and Stability

The MLE process is known for its operational flexibility and stability. It can handle varying influent conditions and is capable of adapting to changes in wastewater composition. This flexibility makes it an attractive option for wastewater treatment plants that experience fluctuations in load or characteristics.

Secondary Benefits for Phosphorus Removal

While the MLE process is primarily designed for nitrogen removal, it can also provide secondary benefits for phosphorus removal. By integrating certain modifications or additional processes, treatment plants can achieve enhanced phosphorus removal, further improving the overall quality of the treated effluent.

In conclusion, the MLE process offers several advantages, including efficient nitrogen removal, energy conservation, operational flexibility, and secondary benefits for phosphorus removal. These benefits make it a highly attractive option for modern wastewater treatment needs.

Limitations and Challenges of MLE Systems

Despite its advantages in wastewater treatment, the Modified Ludzack-Ettinger (MLE) process is subject to certain limitations that can impact its performance.

Temperature and pH Sensitivity

MLE systems can be sensitive to temperature and pH levels. Variations in these parameters can significantly affect the efficiency of the biological processes involved.

Operational Challenges

Operational challenges, including equipment maintenance and process control, are crucial for the smooth functioning of MLE systems.

Addressing Common Problems

Common issues such as bulking and foaming, as well as insufficient carbon sources, need to be addressed to maintain optimal performance.

Bulking and Foaming Issues

Bulking and foaming can lead to operational inefficiencies and affect the overall quality of the treated wastewater.

Insufficient Carbon Sources

Adequate carbon sources are essential for the denitrification process. Insufficient carbon can limit the efficiency of nitrogen removal.

| Factor | Impact on MLE Systems | Mitigation Strategy |

|---|---|---|

| Temperature Fluctuations | Affects microbial activity | Implement temperature control measures |

| pH Variations | Impacts nitrification and denitrification efficiency | Monitor and adjust pH levels regularly |

| Insufficient Carbon Sources | Limits denitrification process | Ensure adequate carbon source supply |

Comparing MLE to Other Wastewater Treatment Methods

Comparing different wastewater treatment processes is crucial for determining the most suitable method for specific treatment needs. The Modified Ludzack-Ettinger (MLE) process is one of several biological nutrient removal processes used in modern wastewater treatment.

Nitrogen Removal Efficiency

When comparing MLE to conventional activated sludge, MLE stands out due to its enhanced nitrogen removal capabilities. MLE’s anoxic and aerobic zones work in tandem to achieve higher denitrification rates.

Process Flexibility

In contrast to sequencing batch reactors (SBRs), MLE offers a continuous flow process that can be more suitable for large-scale wastewater treatment plants. However, SBRs provide flexibility in operation and can be advantageous in certain contexts.

Advanced Nutrient Removal

Compared to Bardenpho and A2O processes, MLE is recognized for its balance between nitrogen removal efficiency and operational simplicity. While Bardenpho and A2O processes offer advanced nutrient removal capabilities, they often require more complex configurations.

Performance Metrics Comparison

Key performance metrics such as nitrogen removal rates, energy consumption, and sludge production are essential for comparing different wastewater treatment processes. MLE generally offers a favorable balance of these metrics, making it a popular choice for many treatment plants.

Ultimately, the choice of wastewater treatment method depends on specific plant requirements, including influent characteristics, effluent standards, and operational constraints. By understanding the strengths and limitations of each process, treatment plant operators can make informed decisions.

Implementing Modified Ludzack-Ettinger in Treatment Plants

Effective implementation of the Modified Ludzack-Ettinger process in treatment plants hinges on understanding its design, retrofit, and operational aspects.

Design Considerations

When designing an MLE system, several factors must be considered, including the size of the treatment plant, the influent wastewater characteristics, and the required effluent quality. Proper design ensures efficient nutrient removal and optimal operation.

The design process involves determining the appropriate size and configuration of the anoxic and aerobic zones, as well as the internal recycle mechanisms.

Retrofitting Existing Facilities

Retrofitting existing facilities to incorporate the MLE process can be a cost-effective way to improve nutrient removal capabilities. Key considerations include assessing the existing infrastructure and determining what modifications are needed to support the MLE process.

Startup and Optimization Strategies

Startup and optimization of the MLE process require careful planning and monitoring. Establishing a robust microbial community is crucial for efficient nutrient removal.

Establishing Microbial Communities

The MLE process relies on a diverse community of microorganisms to perform nitrification and denitrification. Creating conditions that support the growth of these microorganisms is essential for successful operation.

Fine-tuning Operational Parameters

Once the MLE process is operational, fine-tuning parameters such as dissolved oxygen levels, internal recycle rates, and sludge retention time is necessary to optimize performance.

A well-designed and well-operated MLE system can achieve high levels of nutrient removal, as shown in the image below.

Some key benefits of the MLE process include:

- High efficiency in nitrogen removal

- Flexibility in operation

- Potential for phosphorus removal

Case Studies: Successful MLE Implementations

Several case studies highlight the effectiveness of the MLE process in different wastewater treatment applications. These real-world examples demonstrate the process’s efficiency in removing nitrogen and other pollutants from wastewater.

Municipal Wastewater Treatment Applications

In municipal wastewater treatment, the MLE process has been widely adopted due to its ability to effectively remove nitrogen. For instance, a case study from a municipal wastewater treatment plant in the United States showed that the MLE process achieved a nitrogen removal efficiency of over 90%.

Industrial Wastewater Treatment Applications

The MLE process is also used in industrial wastewater treatment, particularly in industries that generate high levels of nitrogenous waste. A case study from a food processing industry revealed that implementing the MLE process resulted in a significant reduction in nitrogen levels, meeting regulatory requirements.

Performance Metrics and Results

The success of MLE implementations can be measured through various performance metrics, including nitrogen removal efficiency, energy consumption, and operational stability. The following table summarizes the performance metrics from several case studies:

| Case Study | Nitrogen Removal Efficiency | Energy Consumption (kWh/m³) |

|---|---|---|

| Municipal WWTP | 92% | 0.35 |

| Industrial WWTP | 85% | 0.40 |

| Food Processing Industry | 88% | 0.38 |

Lessons Learned from Real-World Applications

These case studies provide valuable insights into the successful implementation of the MLE process. Key lessons include the importance of proper design, regular maintenance, and continuous monitoring to ensure optimal performance.

By understanding the successes and challenges faced by these case studies, wastewater treatment plants can better implement the MLE process to achieve efficient biological treatment and meet environmental regulations.

Conclusion

The Modified Ludzack-Ettinger process has emerged as a crucial technology in wastewater treatment, particularly for nutrient removal. By understanding its fundamentals, components, and biochemical processes, treatment plants can achieve efficient nitrogen removal.

The MLE process offers several advantages, including energy conservation, operational flexibility, and secondary benefits for phosphorus removal. Successful implementations in both municipal and industrial wastewater treatment applications demonstrate its effectiveness.

As environmental regulations continue to evolve, the Modified Ludzack-Ettinger process is poised to play a vital role in meeting stringent nutrient removal standards. Its ability to balance efficiency with environmental sustainability makes it an attractive solution for wastewater treatment needs.