Introduction

Wastewater disinfection is a critical process in the treatment of sewage and other contaminated water sources. It involves the removal or inactivation of pathogenic microorganisms to prevent the spread of waterborne diseases and protect public health. The primary purpose of disinfection is to significantly reduce the number of harmful microorganisms in treated wastewater before it is released into the environment or reused for various purposes.

The importance of wastewater disinfection cannot be overstated. Throughout history, waterborne diseases have been a significant cause of illness and death worldwide. The advent of modern wastewater treatment, including disinfection, has dramatically reduced the incidence of these diseases in developed countries. However, in many parts of the world, inadequate wastewater treatment still poses a significant health risk.

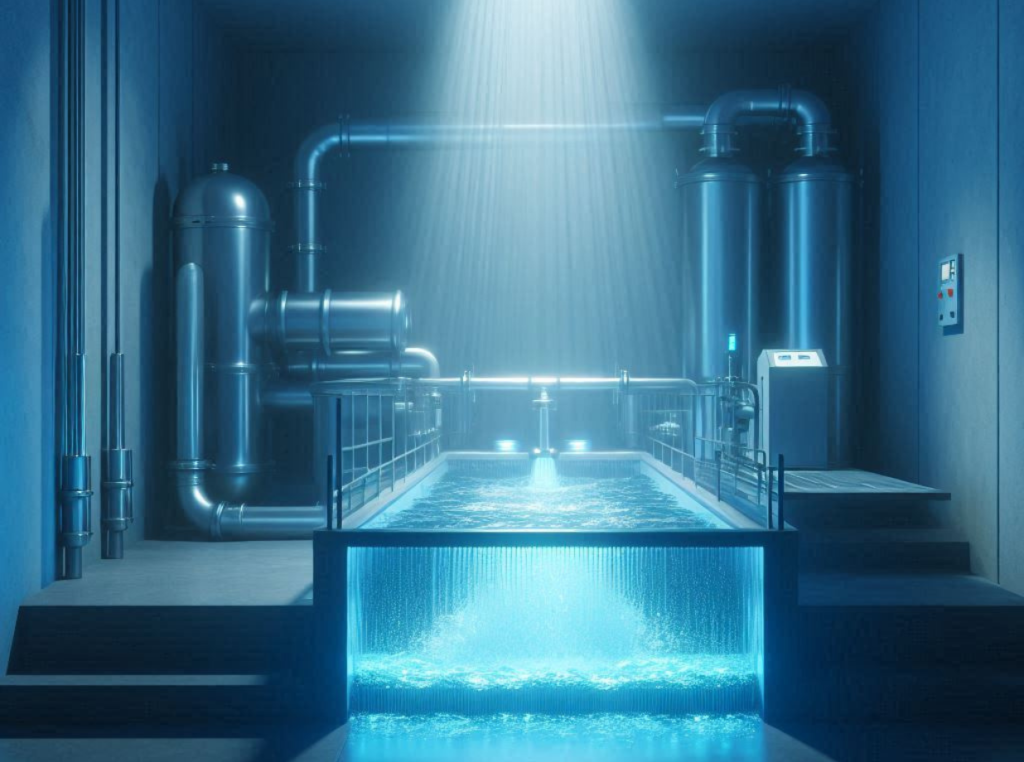

Disinfection is typically the final step in the wastewater treatment process, following primary treatment (physical separation of solids), secondary treatment (biological treatment to remove dissolved and suspended organic matter), and in some cases, tertiary treatment (additional treatment to remove nutrients or specific contaminants). While these earlier stages remove a significant portion of microorganisms, disinfection ensures that the remaining pathogens are eliminated or reduced to safe levels.

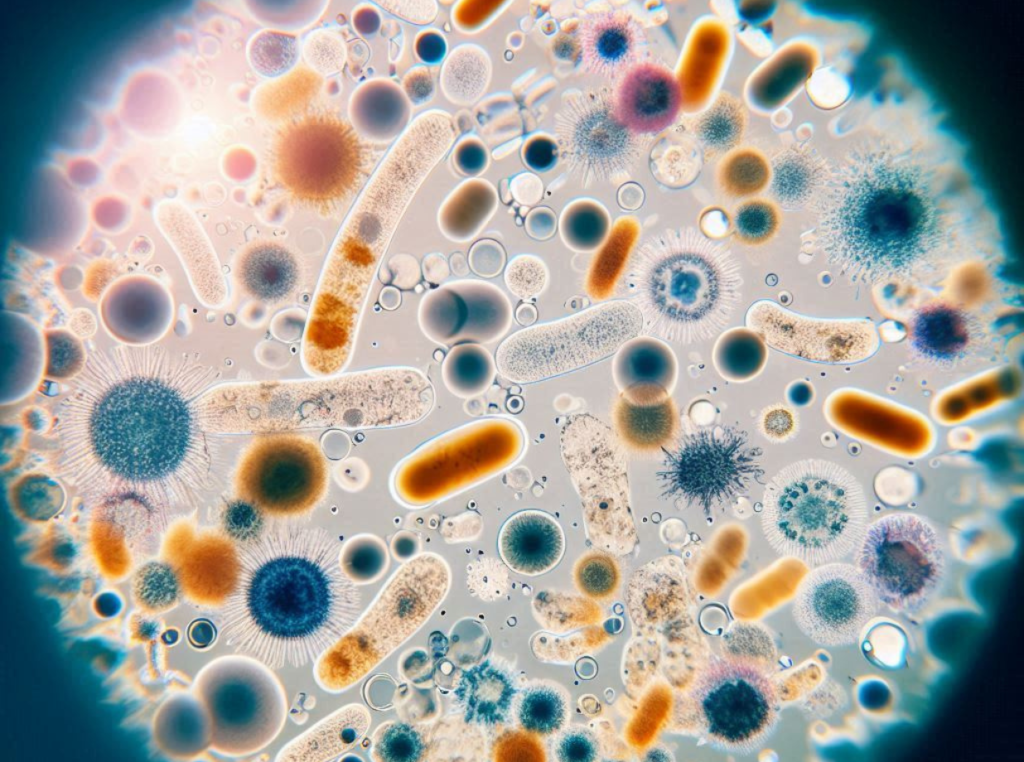

Microorganisms in Wastewater

Bacteria

Bacteria are single-celled microorganisms that can be found in abundance in wastewater. While many bacteria are harmless or even beneficial, some can cause diseases in humans and animals. Bacterial pathogens commonly found in untreated wastewater include:

- Escherichia coli (E. coli): While most strains are harmless, some can cause severe gastrointestinal illness.

- Salmonella: Responsible for salmonellosis, which can cause diarrhea, fever, and abdominal cramps.

- Shigella: Causes shigellosis, a diarrheal disease that can be severe.

- Vibrio cholerae: The causative agent of cholera, a severe diarrheal disease.

- Campylobacter: A common cause of diarrheal illness worldwide.

These bacteria can survive in water for varying periods, making effective disinfection crucial to prevent their spread.

Table 1: Common Bacterial Pathogens in Wastewater

| Pathogen | Disease | Symptoms |

|---|---|---|

| Escherichia coli (E. coli) | Gastroenteritis | Diarrhea, abdominal cramps, fever |

| Salmonella | Salmonellosis | Diarrhea, fever, abdominal cramps |

| Shigella | Shigellosis | Severe diarrhea, fever, abdominal pain |

| Vibrio cholerae | Cholera | Severe watery diarrhea, dehydration |

| Campylobacter | Campylobacteriosis | Diarrhea, cramping, fever, vomiting |

Coliform Bacteria

Coliform bacteria, particularly fecal coliforms, are commonly used as indicator organisms in water quality testing. Their presence suggests the potential contamination of water by fecal matter and the possible presence of other pathogenic organisms.

Total coliforms include bacteria that are found in the soil, in water that has been influenced by surface water, and in human or animal waste. Fecal coliforms are the group of total coliforms that are considered to be present specifically in the gut and feces of warm-blooded animals.

The use of coliforms as indicator organisms is based on several factors:

- They are easy to detect and count in water samples.

- They are generally present in higher numbers than more dangerous pathogens.

- They respond to the environment and treatment processes similarly to many pathogens.

However, it’s important to note that the absence of coliform bacteria doesn’t guarantee the absence of all pathogens, particularly viruses and protozoa.

Pathogenic Organisms

Pathogenic organisms are disease-causing microbes that can be present in wastewater. These include various types of bacteria, viruses, protozoa, and helminths (parasitic worms). Examples include:

- Viruses:

- Hepatitis A and E viruses

- Norovirus

- Rotavirus

- Enteroviruses

- Protozoa:

- Giardia lamblia

- Cryptosporidium parvum

- Entamoeba histolytica

- Helminths:

- Ascaris lumbricoides (roundworm)

- Taenia spp. (tapeworms)

- Trichuris trichiura (whipworm)

These pathogens can cause a range of diseases, from mild gastrointestinal distress to severe and potentially fatal conditions. Many of these organisms are resistant to conventional wastewater treatment processes, making disinfection a crucial step in preventing their spread.

Microorganisms Removed by Treatment Processes

While primary and secondary wastewater treatment processes remove a significant portion of microorganisms, disinfection is necessary to ensure the removal or inactivation of remaining pathogens. The effectiveness of removal varies depending on the specific treatment processes employed:

- Primary Treatment: This stage typically removes 25-50% of bacteria and a smaller percentage of viruses through sedimentation.

- Secondary Treatment: Biological treatment processes can remove 90-99% of bacteria and 80-90% of viruses.

- Tertiary Treatment: Advanced treatment methods like filtration can further reduce microbial populations, removing up to 99.99% of bacteria and 99% of viruses.

Despite these high removal rates, the concentrations of microorganisms in the effluent can still be significant due to the extremely high initial concentrations in raw wastewater. This is why disinfection remains a critical final step in the treatment process.

Table 2: Typical Removal Rates of Microorganisms in Wastewater Treatment

| Treatment Stage | Bacteria Removal | Virus Removal | Protozoa Removal |

|---|---|---|---|

| Primary Treatment | 25-75% | 0-10% | 10-50% |

| Secondary Treatment | 90-99% | 80-90% | 90-95% |

| Tertiary Treatment (Filtration) | 99-99.999% | 95-99% | 99-99.99% |

| Disinfection | 99.9-99.9999% | 99-99.99% | 99-99.99% |

Disinfection Methods

Chlorination

Chlorination is one of the most widely used methods for wastewater disinfection due to its effectiveness and relatively low cost. Chlorine can be applied in several forms, including chlorine gas, sodium hypochlorite solution, or calcium hypochlorite tablets.

- Free Available Residual Chlorine: This refers to the amount of chlorine available in the water for disinfection after the chlorine demand has been satisfied. Free chlorine exists in water as hypochlorous acid (HOCl) and hypochlorite ion (OCl-). HOCl is a much stronger disinfectant than OCl-, and its prevalence is pH-dependent.

- Combined Chlorine (Chloramines): These are compounds formed when chlorine reacts with ammonia in the water. The three types of chloramines are monochloramine (NH2Cl), dichloramine (NHCl2), and trichloramine (NCl3). While less effective than free chlorine, chloramines provide a longer-lasting residual, which can be beneficial in large distribution systems.

- Breakpoint Chlorination: This is the point at which all ammonia has been oxidized, and any additional chlorine exists as free chlorine. The breakpoint occurs when the chlorine dose is approximately 10 times the amount of ammonia nitrogen present. Understanding breakpoint chlorination is crucial for effective disinfection and control of chlorine residuals.

The effectiveness of chlorination depends on several factors:

- Chlorine concentration and form

- Contact time

- pH and temperature of the water

- Presence of interfering substances

- Type and concentration of microorganisms

Other Methods

While chlorination is the focus of this article, it’s worth noting that other disinfection methods exist, each with its own advantages and disadvantages:

- Ultraviolet (UV) Irradiation: UV light damages the genetic material of microorganisms, preventing them from reproducing. UV disinfection is effective against a wide range of pathogens and doesn’t introduce chemicals into the water. However, it provides no residual disinfection, and its effectiveness can be reduced by turbidity in the water.

- Ozonation: Ozone is a powerful oxidant that can effectively inactivate a wide range of pathogens. It’s particularly effective against protozoa like Cryptosporidium, which are resistant to chlorine. However, ozone systems are complex and expensive to operate, and like UV, ozone provides no residual disinfection.

- Peracetic Acid: This organic compound is gaining popularity as a wastewater disinfectant. It’s effective against a wide range of microorganisms and breaks down into harmless by-products. However, it’s more expensive than chlorine and can be corrosive at high concentrations.

- Membrane Filtration: Advanced membrane processes like ultrafiltration and reverse osmosis can physically remove microorganisms from water. While highly effective, these methods are generally too expensive for widespread use in wastewater treatment.

The choice of disinfection method depends on various factors, including regulatory requirements, water quality, cost considerations, and environmental concerns.

Table 3: Comparison of Common Disinfection Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Chlorination | – Effective against most pathogens – Provides residual disinfection – Cost-effective | – Forms disinfection by-products – Less effective against some protozoa – Safety concerns with chlorine gas |

| UV Irradiation | – No chemical addition – Effective against most pathogens – Short contact time | – No residual disinfection – Effectiveness reduced by turbidity – High initial cost |

| Ozonation | – Highly effective against all pathogens – No harmful residuals | – High capital and operating costs – No residual disinfection – Potential for bromate formation |

| Peracetic Acid | – Effective against a wide range of pathogens – Minimal by-product formation | – Higher cost than chlorine – Potential irritant at high concentrations |

Chlorine-based Disinfection

Forms of Chlorine Used

- Chlorine Gas: A greenish-yellow gas that is highly toxic and corrosive. It’s typically stored as a liquefied gas under pressure. Chlorine gas is the most economical form for large treatment plants but requires stringent safety measures due to its hazardous nature. Characteristics:

- Highly effective disinfectant

- Cost-effective for large-scale operations

- Requires specialized handling and safety equipment

- Forms hypochlorous acid when dissolved in water

- Hypochlorite: Commonly used in the form of sodium hypochlorite (liquid bleach) or calcium hypochlorite (solid). Sodium Hypochlorite:

- Liquid form, typically 12.5-15% available chlorine

- Easier to handle than chlorine gas

- Degrades over time, especially in sunlight or at high temperatures

- More expensive than chlorine gas on a per-pound basis

- Solid form, typically 65-70% available chlorine

- More stable than sodium hypochlorite

- Can be used in tablet form for smaller systems

- Requires dissolution before use

- High Test Hypochlorite: A concentrated form of calcium hypochlorite with 65-70% available chlorine. It’s often used in smaller treatment plants or for emergency disinfection due to its stability and ease of storage.

Table 4: Comparison of Chlorine Forms Used in Wastewater Disinfection

| Chlorine Form | Available Chlorine | Advantages | Disadvantages |

|---|---|---|---|

| Chlorine Gas | 100% | – Most economical for large plants – High available chlorine content | – Highly toxic and corrosive – Requires stringent safety measures |

| Sodium Hypochlorite | 12.5-15% | – Easier to handle than chlorine gas – Suitable for smaller plants | – More expensive than chlorine gas – Degrades over time |

| Calcium Hypochlorite | 65-70% | – More stable than sodium hypochlorite – Can be used in tablet form | – More expensive than chlorine gas – Requires dissolution before use |

Chlorine Demand and Residual

Chlorine demand refers to the amount of chlorine consumed by reactions with various substances in the water. These substances include:

- Ammonia and organic nitrogen compounds

- Iron, manganese, and other reduced inorganic compounds

- Organic matter

- Microorganisms

The chlorine residual is the amount of chlorine remaining after these reactions have taken place and is crucial for ongoing disinfection. There are two types of chlorine residual:

- Free Chlorine Residual: This consists of hypochlorous acid (HOCl) and hypochlorite ion (OCl-). It’s a more effective disinfectant than combined chlorine.

- Combined Chlorine Residual: This consists of chloramines formed by the reaction of chlorine with ammonia. While less effective than free chlorine, it provides a longer-lasting residual.

Understanding and controlling chlorine demand and residual is crucial for effective disinfection. Too little chlorine may result in inadequate disinfection, while too much can lead to taste and odor problems, as well as the formation of harmful disinfection by-products.

Oxidation and Reduction Processes

Chlorine acts as a powerful oxidizing agent in water, which is the basis of its disinfection capability. It oxidizes organic matter and inorganic compounds, while also undergoing reduction reactions.

Key oxidation reactions include:

- Oxidation of iron and manganese, converting them to insoluble forms that can be removed by filtration.

- Oxidation of organic compounds, which can improve taste and odor.

- Oxidation of ammonia to form chloramines and eventually nitrogen gas (breakpoint chlorination).

The oxidation of microorganisms’ cellular material is what leads to their inactivation or death. Chlorine can damage cell membranes, interfere with enzyme activity, and damage nucleic acids, all of which contribute to its effectiveness as a disinfectant.

Chlorination Equipment and Processes

Chlorine Injection Points

The point of chlorine injection in the treatment process can significantly affect disinfection efficiency. Common injection points include:

- Pre-chlorination: Chlorine is added at the beginning of the treatment process. This was once common practice but is now less frequently used due to concerns about disinfection by-product formation.

- Post-clarification: Chlorine is added after primary and secondary treatment but before filtration. This allows for a longer contact time and can improve filter performance.

- Post-filtration: Chlorine is added after all treatment processes. This reduces chlorine demand and minimizes disinfection by-product formation but requires careful management to ensure adequate contact time.

- Multiple points: Some plants use a combination of injection points to balance disinfection effectiveness with by-product formation.

The choice of injection point(s) depends on various factors, including water quality, treatment plant configuration, and regulatory requirements.

Eductors and Ejectors

Eductors and ejectors are devices used to safely introduce chlorine gas into the water stream. They use the vacuum created by flowing water to draw chlorine gas into the system.

Eductor operation:

- Water flows through a venturi, creating a vacuum.

- The vacuum draws chlorine gas from the chlorine cylinder.

- Chlorine gas mixes with the water in the eductor.

- The chlorine solution is injected into the main water flow.

Ejectors work on a similar principle but are typically used for larger installations. They can handle higher chlorine feed rates and create a stronger vacuum.

Advantages of eductor/ejector systems:

- Safe handling of chlorine gas

- Efficient mixing of chlorine and water

- Ability to handle varying chlorine demand

Air Gap Systems

Air gap systems provide a physical separation between the potable water supply and the chlorine injection system, preventing backflow and ensuring safety. An air gap is a vertical physical separation between the outlet of a water supply pipe

Resources

- Centers for Disease Control and Prevention (CDC) – Waterborne Diseases

Learn more about waterborne pathogens, prevention, and treatment. - World Health Organization (WHO) – Water Sanitation and Health

Explore global information on water-related diseases and health guidelines. - Environmental Protection Agency (EPA) – Ground Water and Drinking Water

Stay updated on drinking water standards and safety practices.