Have you ever wondered how wastewater treatment facilities manage to handle the diverse and challenging materials they encounter daily? One of the critical components in making this possible is the positive displacement pump. These pumps play a vital role in ensuring smooth operations by maintaining consistent flow rates while handling difficult materials. Let’s journey through the unique contributions of positive displacement pumps in wastewater treatment, their applications, benefits, and future trends.

Introduction

Wastewater treatment is a complex process that involves the removal of contaminants from wastewater to produce water that can be safely returned to the environment. The journey from dirty to clean water involves several steps, each with unique challenges. Central to many of these steps is the need for reliable pumping systems that can handle various materials, including solids, sludges, and chemicals.

Overview of Wastewater Treatment Challenges

Wastewater presents a variety of challenges due to its complex composition, which includes organic materials, solids, industrial chemicals, and microorganisms. Treating wastewater requires systems capable of handling these materials effectively to prevent any disruption in the treatment process.

Importance of Reliable Pumping Systems

Pump failures can lead to costly downtime, environmental damage, and regulatory fines. Hence, the importance of having reliable pumping systems cannot be overstated. Such systems must handle a wide variety of tasks while maintaining the ability to move fluids efficiently and safely.

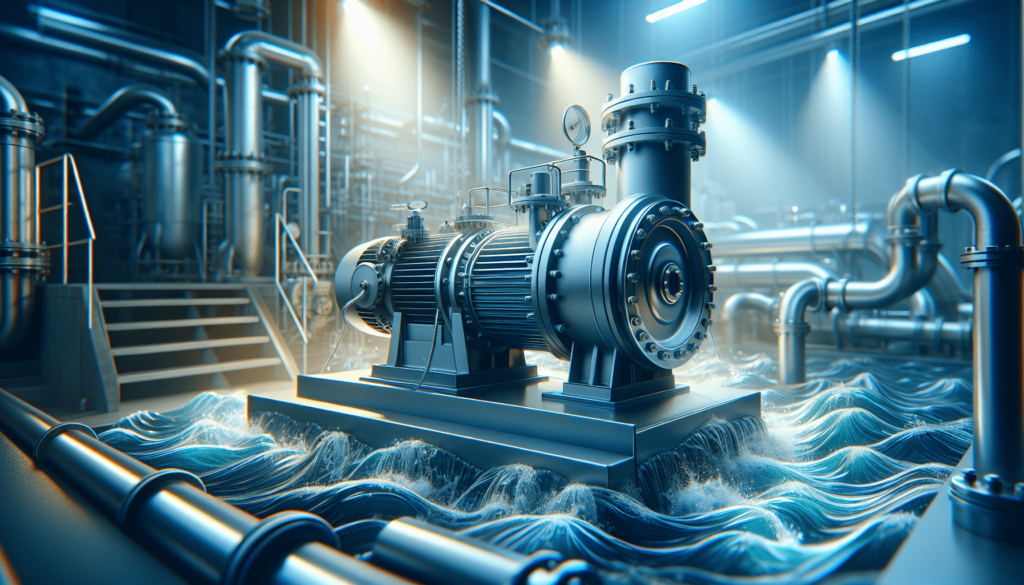

Brief Introduction to Positive Displacement Pump Technology

Positive displacement pumps are specially designed to handle complex materials found in wastewater treatment. Unlike centrifugal pumps, which rely on high-speed rotation to move fluids, positive displacement pumps transport fluid by trapping a fixed amount and forcing it through the pump’s discharge. This mechanism enables them to maintain a consistent flow, regardless of pressure changes.

Technical Background

Understanding the technology behind positive displacement pumps helps highlight why they are indispensable in wastewater treatment.

Types of Positive Displacement Pumps Commonly Used in Wastewater

In wastewater treatment, various types of positive displacement pumps are utilized, each with specific operational advantages:

- Progressive Cavity Pumps: Known for their capability in handling viscous and abrasive fluids, these pumps feature a rotor that moves within a helically shaped cavity.

- Rotary Lobe Pumps: These pumps are designed with two or more lobes that move fluid through the pump. They excel in transferring solids-laden materials with minimal energy.

- Peristaltic Pumps: These pumps utilize a “squeeze and release” motion to move fluids, ideal for chemical dosing due to their precise flow control.

Operating Principles and Mechanical Advantages

Positive displacement pumps work by creating an expanding cavity on the suction side and a decreasing cavity on the discharge side. This mechanical advantage allows them to function with high efficiency in both low and high-pressure environments, making them suitable for varying application needs.

Flow Rate Characteristics and Pressure Handling Capabilities

A standout feature of positive displacement pumps is their ability to maintain a consistent flow rate, independent of the discharge pressure. This characteristic is crucial in applications where maintaining a steady flow is essential, such as when dosing chemicals into the wastewater stream.

Applications in Wastewater

Positive displacement pumps are integral to many processes within wastewater treatment, making difficult tasks achievable with precision and reliability.

Sludge Handling and Transfer

Sludge, a byproduct of wastewater treatment, is notoriously challenging to handle due to its thickness and heavy solids content. Positive displacement pumps handle sludge with ease, enabling its transfer and further treatment or disposal.

Chemical Dosing and Injection

Accurate dosing of chemicals is critical for controlling pH levels and eliminating pathogens. Peristaltic pumps, known for their precision, make them ideal for this application, ensuring the right amount of chemical is added to the wastewater stream.

Dewatering Processes

During dewatering, water is removed from sludge to reduce its volume before disposal. Positive displacement pumps are used to facilitate this process, effectively managing high-solids content and improving overall efficiency.

High-Solids Content Applications

Applications involving thick slurries and heavy solids require pumps that can handle high pressures without losing flow consistency. Positive displacement pumps are equipped to manage these materials, reducing energy expenditure and operating costs.

Advantages and Benefits

The use of positive displacement pumps in wastewater treatment offers several advantages that are hard to ignore.

Handling of Viscous Materials

Their design allows positive displacement pumps to move viscous materials efficiently. This means they can handle anything from thick sludge to fibrous waste without clogging or impeding the flow.

Consistent Flow Rates Regardless of Pressure Variations

Positive displacement pumps maintain a consistent flow rate, a crucial advantage when dealing with processes that require precise control. This consistency ensures optimal treatment performance, regardless of variations in pressure.

Self-Priming Capabilities

Unlike some other pump types, many positive displacement pumps are naturally self-priming. This means they can evacuate air on their own and start processing without additional intervention, offering convenience and operational readiness.

Accuracy in Dosing Applications

Accurate dosing is vital for chemical processes, and the precision of positive displacement pumps in handling this is unmatched. Whether it’s adding reactants or neutralizing pathogens, the precision of these pumps ensures effective treatment outcomes.

Maintenance and Operational Considerations

Maintaining operational efficiency requires an understanding of common wear patterns and proactive maintenance strategies.

Common Maintenance Requirements

Regular inspection and maintenance are crucial to extending the lifespan of positive displacement pumps. This may include checking seals, lubricating moving parts, and ensuring the pump is free of blockages.

Wear Patterns and Component Lifecycle

Understanding wear patterns, such as those on rotors and casings, allows for timely maintenance and replacement, preventing unexpected failures. Each component has a defined lifecycle, which should be monitored to maintain efficiency.

Troubleshooting Strategies

Having a set troubleshooting protocol can help quickly resolve common issues like reduced flow rates or pressure drops. Strategies may include inspecting seals for leaks, checking for obstructions, or recalibrating dosing systems.

Best Practices for Optimal Performance

Implementing best practices, such as regular maintenance schedules and proper component handling, ensures optimal pump performance. Training staff on these practices further enhances reliability and operational efficacy.

Case Studies

Examining real-world examples helps illustrate how positive displacement pumps have been successfully applied in wastewater treatment.

Real-World Examples of Successful Implementations

A municipal wastewater treatment facility faced challenges with their current pump system’s inability to handle high solids. Switching to positive displacement pumps not only resolved the clogging issues but improved overall efficiency and reduced maintenance costs.

Problem-Solving Scenarios

In another scenario, a facility dealing with fluctuating chemical dosing rates saw significant improvements after adopting peristaltic pumps, which allowed for precise chemical management, leading to better compliance with environmental standards.

Cost-Benefit Analyses

Initial investments in positive displacement pumps can be offset by long-term savings in maintenance and operational costs, making them a cost-effective solution for many treatment facilities.

Future Trends

The future of wastewater treatment and pump technology is evolving, with exciting developments on the horizon.

Emerging Technologies in Positive Displacement Pump Design

Innovations such as improved material sciences and digital integration are paving the way for more durable and efficient positive displacement pumps, capable of handling even more challenging environments.

Integration with Smart Systems and Automation

The advent of smart technology is leading to the development of automated systems that monitor and adjust pump operations in real-time, ensuring optimal performance and energy efficiency.

Sustainability Considerations

Sustainable practices are becoming increasingly important. Positive displacement pumps, with their energy-efficient operations and reduced waste generation, align well with the sustainability goals of modern treatment facilities.

Conclusion

Exploring positive displacement pumps reveals their critical role in tackling the unique challenges of wastewater treatment. Their ability to handle viscous materials, maintain consistent flow rates, and ensure precise dosing makes them indispensable to the industry. With advancements in technology and increasing focus on sustainability, these pumps will continue to adapt, providing efficient solutions for the future of wastewater management.

By understanding the capabilities, maintenance needs, and future trends of positive displacement pumps, you can ensure their effective implementation in various wastewater treatment applications, supporting both operational efficiency and environmental protection.

Resources

- North Ridge Pumps – What Are Positive Displacement Pumps?

- ScienceDirect – Positive Displacement Pumps – An Overview

- DAE Pumps – Most Common Types of Positive Displacement Pumps

- PSG Dover – Positive Displacement Pumps – PSG Dover