Amidst a plethora of techniques, air lift pumps have emerged as a revolutionary option to address the complexities of managing wastewater. Let’s embark on a journey to understand how these pumps work and why they’re making waves in the field of wastewater management.

Understanding Air Lift Pumps

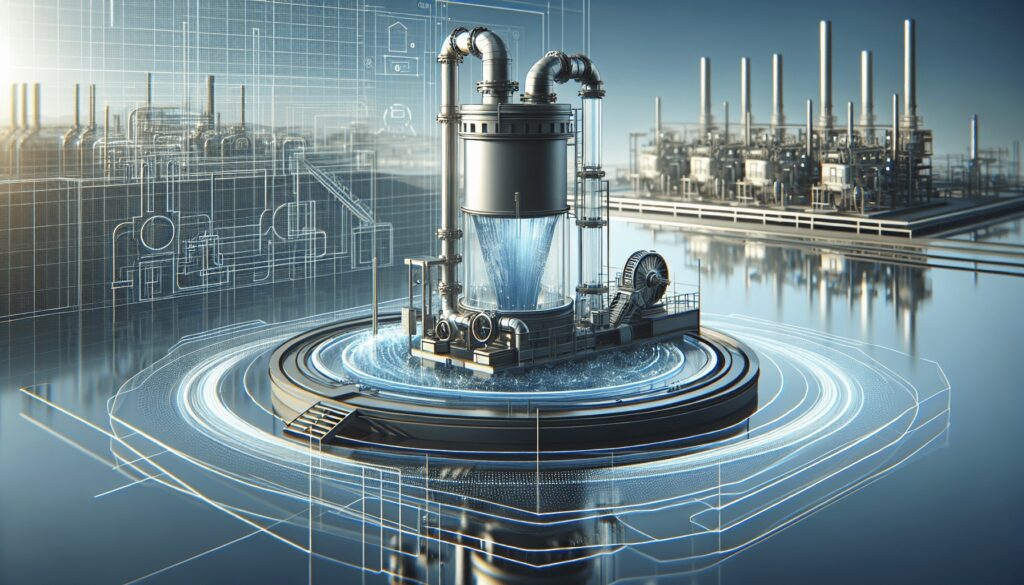

At first glance, the term “air lift pump” might conjure an assembly of complex machinery, but the principle behind it is strikingly simple yet impactful. In essence, an air lift pump utilizes compressed air to lift water and other fluids, including the slurry that constitutes wastewater. But how exactly does this process unfold?

Basic Working Principle

The mechanics of an air lift pump are founded on the concept of buoyancy. Compressed air is introduced into a pipe submerged in the fluid, often wastewater, at a lower depth. As air bubbles rise through the liquid column, they decrease the overall density of the fluid within the pipe. This reduced density leads to an upward motion, effectively pushing the fluid to the surface. The simplicity of this design belies its efficiency, making it a valuable asset in wastewater management.

Components of an Air Lift Pump

To grasp the entirety of how air lift pumps function, it’s crucial to familiarize yourself with their core components. The primary elements include:

- Air Compressor: This provides the necessary compressed air.

- Riser or Discharge Pipe: The main channel through which fluid is transported.

- Airline or Sparger: Delivers air into the submerged pipe.

- Pump Housing: Encases and supports the mechanism.

Understanding these components aids in appreciating the streamlined and minimalistic nature of air lift pumps, which lies at the heart of their innovative application in wastewater treatment.

Advantages of Air Lift Pumps

You might be curious about why air lift pumps are being touted as a superior solution in wastewater management. The reasons are compelling, serving both functional and environmental objectives.

Energy Efficiency and Cost-Effectiveness

Compared to mechanical pumps, air lift pumps are remarkably energy-efficient. With fewer moving parts, these pumps require minimal maintenance and operational oversight, thus reducing overall costs. This energy efficiency doesn’t just translate to lowered operational costs, but also less environmental impact from power consumption.

Non-Clogging Design

One of the enduring challenges of managing wastewater is dealing with debris and solids. Unlike traditional pumps, air lift pumps are designed to handle these with ease. By virtue of their mechanism, these pumps can lift fluids containing a variety of suspended solids without the risk of clogging, a significant advantage in waste-heavy environments.

Simplicity and Reliability

Air lift pumps are designed with simplicity as a keystone, making them exceedingly reliable. The absence of complex mechanical parts minimizes the potential for breakdowns, ensuring continuous operation, which is vital for the critical infrastructure of wastewater treatment facilities.

Environmentally Friendly

The low environmental footprint of air lift pumps complements their functional benefits. These pumps reduce reliance on fossil fuel-driven power more than traditional mechanical pumps, aligning with global efforts towards more sustainable and environmentally friendly practices.

Applications in Wastewater Management

Air lift pumps are not a one-size-fits-all solution, but their versatility ensures they find a place in various stages and types of wastewater management.

Sewage Treatment Plants

In the journey of wastewater from domestic or industrial sources to treatment plants, air lift pumps provide a crucial link. They efficiently transport sewage across different treatment stages, leveraging their ability to manage fluid with high solid content without clogging.

Sludge Management

Handling the byproduct of wastewater treatment — sludge — is pivotal. Air lift pumps shine here, thanks to their robustness in transporting dense mixtures of solids and liquids, ensuring that sludge can be processed or disposed of safely and efficiently.

Aquaculture and Algal Cultivation

Beyond traditional applications, air lift pumps are making inroads into unconventional territories like aquaculture and algal cultivation. In such settings, these pumps circulate water without harming fish or delicate algae, thereby maintaining optimal conditions for growth.

Innovations and Future Prospects

The advent of air lift pumps itself marked a substantial innovation in wastewater management, yet the journey of innovation is far from over. As technology advances, so too does the potential for these pumps to evolve and adapt to ever-changing environmental and industrial needs.

Integration with Smart Technologies

Imagine a landscape where air lift pumps are integrated with smart technologies, offering real-time data and analytics on fluid levels, pump efficiency, and maintenance needs. This fusion of traditional mechanical principles with modern technology heralds a future of intelligent wastewater management systems, ensuring resource optimization and waste minimization.

Scalability and Customization

The future of air lift pumps lies in customization and scalability, adapting to diverse industrial landscapes. From urban settings requiring compact solutions to large-scale industrial operations, these pumps can be tailored to suit specific demands. This adaptability ensures that the growth of air lift pump applications will keep pace with global industrial advancement.

Environmental Impact Assessment

Continuous research into the environmental benefits of air lift pumps remains crucial. By thoroughly understanding their impact on carbon footprints and ecological balance, the industry can enhance design and operational methodologies to boost the green credentials of wastewater treatment as a whole.

Potential Challenges and Considerations

As promising as air lift pumps are, they are not without challenges. Being aware of these can help in mitigating any operational hurdles that might arise.

Large-Depth Limitations

One notable limitation is their efficiency at significant depths. Because air lift pumps rely on buoyancy, their ability to lift fluids diminishes with depth. Thus, they might be less effective in deep water applications without augmentations or additional design considerations.

Air Supply Demands

Continuous and consistent air supply is paramount for the operation of air lift pumps. In scenarios where air supply is erratic, the pumps may experience decreased efficiency or stoppages, necessitating dependable air compressors and energy sources.

Noise and Aesthetic Concerns

The operation of air lift pumps, while generally quiet, can become a concern in areas where noise pollution is regulated, requiring additional measures like soundproofing. Additionally, the industrial look of air lift systems may not always align with aesthetic goals, especially in commercial or residential settings.

The Way Forward

The path forward for air lift pumps in wastewater management is one of promise and potential. The ongoing evolution and adaptation of this technology will require collaboration among engineers, environmentalists, and policymakers to ensure its continued effectiveness and environmental alignment.

Education and Awareness

Raising awareness about the benefits and functioning of air lift pumps can usher in broader acceptance and adoption. Educational initiatives targeting stakeholders at every level can facilitate greater understanding and support for innovative wastewater solutions.

Policymaking and Regulation

As the role of air lift pumps in sustainable wastewater management grows, supportive policymaking and regulation will be essential. By fostering environments conducive to research, development, and deployment of these technologies, policymakers can actively contribute to a cleaner and more sustainable future.

Continuous Innovation

Innovation is the lifeblood of any technology, and air lift pumps are no exception. New materials, engineering designs, and digital integrations hold the key to overcoming current limitations and unlocking new applications.

In conclusion, air lift pumps are more than mere mechanical wonders; they symbolize a shift toward smarter, cleaner, and more efficient wastewater management practices. By embracing these technologies, you play a role in crafting a future where sustainability is seamlessly interwoven into the infrastructure of the modern world.