In the realm of water treatment, the ability to measure flow precisely impacts the efficiency and efficacy of the entire system. One of the primary tools relied upon for this purpose are wastewater flumes, which come in various types, each tailored to specific environments and needs. Understanding their importance and the technology behind them is essential for anyone involved in wastewater treatment.

What Are Flumes?

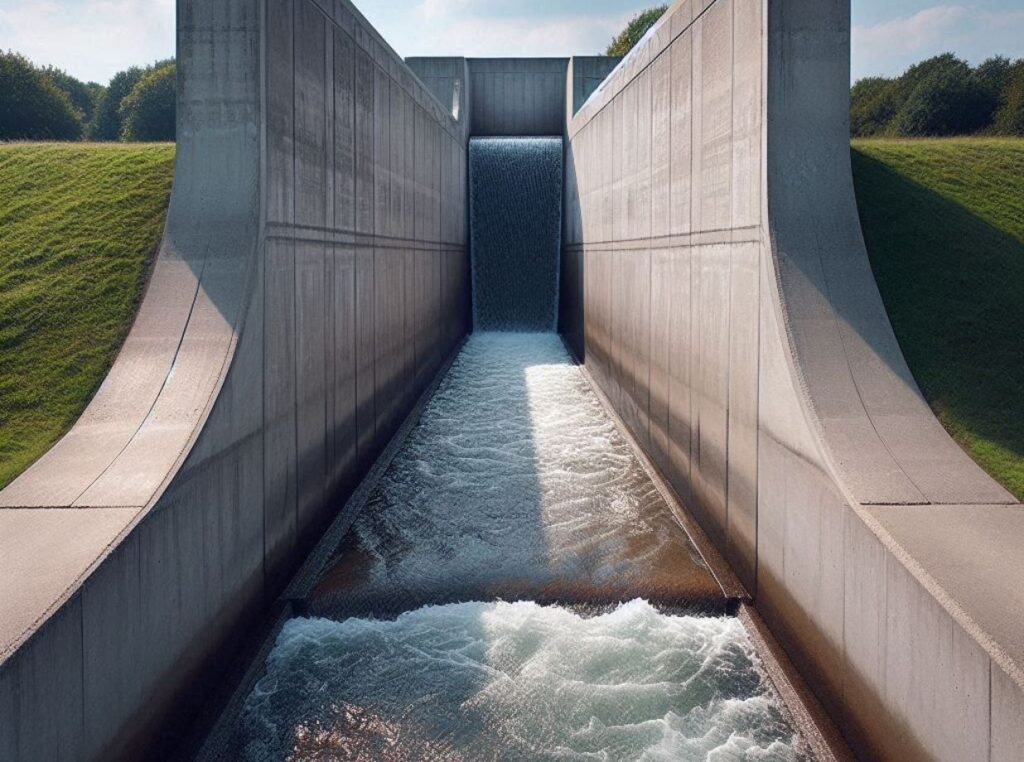

Flumes are engineered channels designed to measure the flow of water in open streams and pipes. In the context of wastewater treatment, they play a vital role by providing reliable data that can guide facility operations, influence environmental compliance, and optimize treatment processes. Accurate flow measurement is not just a technical necessity but a statutory requirement. Poor measurement can lead to inefficiencies, regulatory non-compliance, and elevated operation costs.

The Critical Role of Flumes in Wastewater Treatment

In wastewater treatment, flumes are essential because they enable the accurate measurement of water flow, which is crucial for system optimization and regulatory adherence. They help monitor the influent and effluent flow rates, which are key parameters in the management of treatment facilities.

Why Accurate Flow Measurement Matters

Accurate flow measurement allows operators to control the treatment process more effectively, ensuring that chemical inputs are matched to the water volume and influencing the biological treatment processes positively. It also aids in billing purposes for water utilities and helps in the evaluation of system design for future expansion or modification. Inaccuracies can result in either over-treatment, leading to wasted resources, or under-treatment, which may cause environmental harm and legal issues.

A Brief History of Flume Development

The history of flumes dates back to early hydrology studies when there was a need to measure the flow of natural streams accurately. The development of standardized flume designs over time has transitioned from simple constructions to more scientifically validated designs like the Parshall Flume, which has become the industry benchmark due to its reliability and ease of use.

A Technical Overview of Flumes

How Flumes Work

Flumes operate on the principles of open-channel flow measurement. By forming a constriction in the channel, they create a relationship between the water level (head) and the flow rate. As water passes through the narrowed section of a flume, the velocity and depth change, allowing flow rates to be determined using established equations.

Common Terminology

Here are some terms you’ll frequently encounter when discussing flumes:

- Flow Rate: The volume of fluid passing through a section per unit of time.

- Head: The depth of water in the flume.

- Subcritical Flow: When the water flow is primarily affected by the downstream conditions.

- Supercritical Flow: When the flow is mostly determined by the upstream conditions.

- Critical Flow: The transition point between subcritical and supercritical flow.

General Benefits of Using Flumes

Compared to other flow measurement devices, flumes offer several advantages:

- High Accuracy: Less influenced by velocity profile distortions.

- Ease of Maintenance: Fewer moving parts decrease the need for frequent maintenance.

- Compatibility with Sanitary Conditions: Suitable for wastewater environments where other sensors may fail.

A Detailed Analysis of Each Flume Type

Parshall Flume

The Parshall Flume is widely regarded as the industry standard for wastewater measurement, attributable to its consistent performance across various conditions.

Why It’s the Industry Standard

Parshall Flumes have become the go-to choice due to their high accuracy, ability to handle variable flow conditions effectively, and well-documented flow rate equations.

Design Features and Operation

These flumes feature a narrowed throat and an angled entrance to smoothly transition the flow into supercritical conditions. This design minimizes head loss and maximizes measurement precision.

Typical Applications

Commonly used in irrigation canals, wastewater treatment plants, and septic system outflows, this flume handles a significant range of flow rates.

Installation Requirements

The installation involves ensuring a level alignment to maintain accuracy, and secure ground fixing to prevent settlement over time that could interfere with measurements.

Maintenance Considerations

Regular inspections to clear sediment buildup and ensure there are no obstructions in the approach and throat sections help maintain accuracy.

Palmer-Bowlus Flume

Perfectly suited for sanitary sewer applications, the Palmer-Bowlus Flume is celebrated for its adaptability and effectiveness.

Advantages in Sanitary Sewers

The Palmer-Bowlus Flume is specially designed for installation within circular pipes, offering a seamless fit that’s ideal for urban sewer systems.

Installation Process

Installation requires minimal alteration to existing pipelines, making it a cost-effective choice for updates in established sewers.

Flow Range Capabilities

This flume is especially adept at handling varying flow ranges, accommodating typical urban flow fluctuations effectively.

Cost Considerations

A relatively low-cost option, the Palmer-Bowlus Flume requires less channel modification, further reducing installation costs.

H-Flume

The H-Flume is particularly effective for low flow conditions, where precision is paramount.

Low Flow Measurement Benefits

This flume is engineered to provide accurate measurements in conditions where other devices might struggle, particularly in low-volume streams.

Sediment Handling Features

Designed with sediment management in mind, the H-Flume prevents blockages, ensuring consistent performance.

Design Characteristics

The simple geometry with a flat base facilitates installation and cleaning, making it a practical option for remote locations.

Best Use Scenarios

Best suited for small wastewater systems and agricultural runoff monitoring, where maintaining consistent flow ratings is crucial.

Montana Flume

When space is a premium concern, the Montana Flume offers a compact solution without sacrificing precision.

Comparison with Parshall

While both are effective, the Montana Flume’s simpler design can be advantageous in confined environments where space-saving is necessary.

Space-Saving Benefits

The compact design meets the need for accurate measurement in tight spaces, making it ideal for small-scale applications.

Cost-Effectiveness Analysis

Lower manufacturing costs make it an economical choice, with comparable accuracy to more complex flume systems.

Installation Advantages

The Montana Flume’s straightforward installation process translates into reduced labor hours and disruptions.

Trapezoidal Flume

Noted for its simple construction yet effective performance, the Trapezoidal Flume shines in sediment-heavy environments.

Construction Simplicity

With straight, angled sides, these flumes are easier and cheaper to construct, particularly at large scales.

Performance Characteristics

Their design facilitates debris passage, reducing maintenance frequency, and preserving measurement integrity.

Sediment Management

The configuration allows sediments to pass through without affecting readings significantly, a significant advantage in agricultural and mining applications.

Cost Benefits

Economical to produce and maintain, trapezoidal flumes offer significant lifecycle cost savings.

RBC Flume

The RBC Flume is specialized for use in rectangular channels while providing high accuracy in low-flow conditions.

Rectangular Channel Applications

Ideal for retrofitting into existing rectangular conveyance structures without significant reconducting.

Low Flow Accuracy Features

These flumes excel in low-flow conditions, delivering precise measurements often required in stringent monitoring scenarios.

Installation Process

The installation is straightforward, with often negligible need for upstream and downstream channel modification.

Head Loss Advantages

The RBC Flume design minimizes head loss, preserving the hydraulic profile while ensuring accurate readings.

Selection Guide

Choosing the right flume can be challenging, given the variety of options available. Key considerations include:

Factors to Consider When Choosing a Flume

- Site Requirements: Space and environmental conditions at the installation site.

- Flow Range Considerations: Expected flow variability and range.

- Budget Constraints: Initial installation costs and long-term maintenance budgets must align.

Best Practices for Installation and Maintenance

Installation Tips

Ensuring alignment and secure fitting during installation prevents measurement inaccuracies and equipment damage.

Maintenance Requirements

Regular monitoring and clearing of debris, coupled with periodic recalibration, ensure sustained measurement accuracy.

Calibration Procedures

Performing routine recalibration with certified instruments ensures data reliability and process efficiency.

Common Troubleshooting

Watch for obstructions in the flume and verify head measurement devices for faults, ensuring swift correction to maintain accuracy.

Future Trends in Flume Technology

Emerging technologies promise to reshape the landscape of flow measurement in wastewater treatment.

Emerging Technologies in Flume Design

Development of composite materials and innovative designs aim to increase accuracy further and reduce costs.

Integration with Digital Monitoring Systems

The fusion of IoT (Internet of Things) with flume systems allows for real-time data acquisition and remote monitoring, revolutionizing water management strategies.

Sustainability Considerations

Future flume designs are expected to focus on eco-friendliness, utilizing sustainable materials and reducing energy footprints in manufacturing and operation.

Conclusion and Next Steps

As technology evolves, so does the importance of flumes in wastewater management. The choice of the right flume involves careful consideration of various factors, including site-specific requirements and budget considerations. For those considering installation or upgrades, partnering with experienced suppliers and installers guarantees that the system will deliver the most reliable flow measurements, optimizing your facility’s effectiveness and compliance. Now, it’s time to assess your facilities and consider how flumes might enhance your water management practices, ensuring efficiency and sustainability for years to come.