Have you ever wondered about the processes that help manage wastewater treatment effectively? One such method that has gained attention for its efficiency and effectiveness is the Fixed Film Wastewater Process. As you navigate through this article, you’ll gain a deeper understanding of what this process entails, how it works, and its advantages over other kinds of wastewater treatment methods.

Introduction to Wastewater Treatment

Before diving into the specifics of the fixed film process, it’s important to get a grasp on wastewater treatment as a whole. Wastewater treatment involves removing contaminants from water that has been affected by domestic, industrial, or commercial use. The aim is to produce an effluent that can be returned safely to the environment or reused. Treatment methods vary, but they generally include physical, chemical, and biological processes.

What is the Fixed Film Wastewater Process?

The fixed film wastewater process is a biological treatment method where microorganisms are used to remove organic matter from wastewater. Unlike other wastewater treatment processes in which microorganisms are suspended in the treatment water (such as activated sludge), fixed film processes involve attaching microorganisms to a surface.

With this method, the microorganisms are fixed or attached to a solid medium such as rocks, gravel, or specially designed plastic media. These fixed surfaces create an environment where microorganisms can thrive and process waste effectively.

The Role of Microorganisms

Microorganisms play a crucial role in wastewater treatment by breaking down organic matter. In a fixed film system, these microorganisms form a slime layer, or biofilm, on the media’s surface. As wastewater flows over these surfaces, the biofilm microorganisms consume and break down the organic pollutants.

Types of Fixed Film Processes

There are several types of fixed film processes, each with its own unique approach and materials. Understanding these types helps illustrate the versatility and adaptability of fixed film methods in various treatment scenarios.

Trickling Filters

A trickling filter consists of a bed of media over which wastewater is distributed. As the wastewater trickles down through the filter, it comes into contact with the microorganisms growing on the media surface. Here’s a simple breakdown:

- Media: Rocks, gravel, slag, or plastic media support microorganism growth.

- Structure: Wastewater is distributed over the media via a rotary arm or other distribution devices.

- Process: Wastewater percolates down through the media, and the biofilm consumes the organic pollutants.

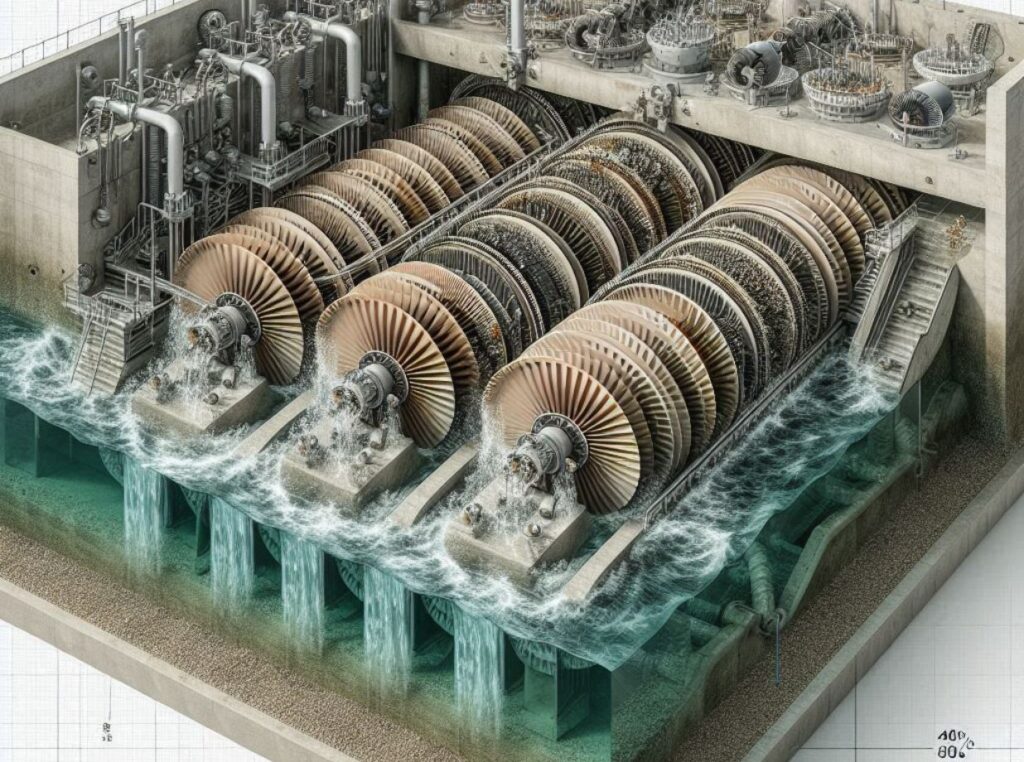

Rotating Biological Contactors (RBCs)

In RBCs, a series of closely spaced disks rotate while partially submerged in the wastewater. The biofilm forms on these disks, and as they rotate, they come into contact with both air and the wastewater, allowing for efficient microbial activity. Key points include:

- Disks: Usually made of plastic material, providing a large surface area.

- Rotation: Facilitates oxygen transfer and wastewater contact.

- Efficiency: Effective for treating wastewater with fluctuating loads and composition.

Biological Aerated Filters

Biological Aerated Filters (BAFs) incorporate submerged media where air is blown through to support aerobic microbial activity. This process is great for:

- Filtration and Cleaning: Filters remove solids while biofilm performs biological treatment.

- Compact Design: Space-saving compared to traditional setups.

- Flexibility: Can handle various wastewater treatment stages, including nitrification and denitrification.

Advantages of Fixed Film Processes

Fixed film processes offer numerous advantages, making them a favored choice in many wastewater treatment scenarios. Here’s a comprehensive look at those benefits:

Stability and Efficiency

Because the biofilm is attached to a fixed surface, fixed film processes can handle shock loads better than suspended growth systems like activated sludge. This stability ensures consistent treatment even with fluctuating input conditions.

Lower Sludge Production

Fixed film systems typically produce less excess sludge compared to traditional systems. This reduction is due to the continuous growth and sloughing of the biofilm, which better regulates biomass production.

Reduced Operational Costs

With fewer sludge handling and disposal issues, operational costs are usually lower. Additionally, the processes are generally less energy-intensive. For example, trickling filters don’t require aeration which significantly cuts energy usage.

Less Operator Intervention

The self-regulating nature of fixed film systems means they often require less frequent monitoring and intervention. This attribute results in reduced labor costs and simpler operation overall.

Challenges and Considerations

Despite their advantages, fixed film processes are not without challenges. Being aware of these can help you decide if this technology is suitable for a specific application.

Biofilm Control and Management

Over time, the biofilm may grow too thick, leading to clogging and reduced system efficiency. Regular maintenance and monitoring are necessary to avoid these issues and ensure optimal performance.

Media and Infrastructure

The choice of media can affect both initial installation costs and maintenance. Different materials have varied longevity, degradation rates, and resistance to chemical and biological degradation.

Seasonal Variations

Temperature changes may impact microorganism activity. In colder climates, special precautions are needed to maintain efficiency during winter months.

Comparison with Other Wastewater Treatment Processes

When deciding on a wastewater treatment method, it’s important to compare different processes to determine which is most suitable for specific needs.

| riteria | Fixed Film Processes | Activated Sludge |

|---|---|---|

| Biomass Retention | High due to attached biofilm | Lower as biomass is suspended |

| Energy Consumption | Generally lower | Higher due to aeration needs |

| Sludge Production | Lower | Higher |

| Operational Stability | High, less sensitive | Can be sensitive to load changes |

| Footprint | Smaller | Larger, especially for aeration tanks |

Emerging Trends and Innovations

Wastewater treatment technologies continually evolve, and fixed film processes are no exception. Keeping an eye on new trends can help you stay ahead and leverage advanced techniques.

Integrated Systems

Integrating fixed film with other treatment processes can further enhance efficiency. Hybrid systems that combine trickling filters with activated sludge processes are an example of this trend aiming to improve treatment outcomes.

Advanced Materials

The development of materials that offer superior performance characteristics, such as increased durability or enhanced microbial activity, is another exciting innovation. These materials could potentially redefine the efficiency and lifespan of fixed film systems.

Smart Monitoring and Automation

Incorporating IoT and AI-driven solutions into wastewater systems allows for real-time monitoring and optimization. This innovation not only enhances treatment efficiency but also reduces maintenance and operational costs.

Conclusion

Embarking on a journey through the fixed film wastewater process reveals a world of balance between nature and technology. By harnessing the natural prowess of microorganisms, fixed film processes provide a sustainable, efficient, and often cost-effective method for treating wastewater. As advancements continue to shape this field, staying informed ensures you can make the most of these technologies, driving progress in both environmental stewardship and resource management.