Wastewater systems need reliable valves to handle corrosive liquids, debris, and high-pressure flows. Butterfly valves and gate valves are two common options. They have different designs and performance. This article will help professionals choose the right valve for their needs.

Key Takeaways

- Butterfly valves offer compact design for space-limited wastewater infrastructure.

- Gate valves provide full bore passages critical for high-volume sewage flow.

- Material compatibility affects longevity in corrosive wastewater environments.

- Operation torque differences impact maintenance routines in treatment plants.

- Cost comparisons matter for large-scale wastewater infrastructure projects.

Introduction to Wastewater Valve Systems

Wastewater treatment valves are key to our modern sanitation systems. They control flow, pressure, and containment. These systems handle millions of gallons of water every day. Let’s see how they work and why choosing the right valves is important.

Overview of Wastewater Treatment

Wastewater goes through steps like screening, aeration, and disinfection. Valves help move water between these stages. For instance, butterfly or gate valves manage sludge transfer or chemical injection.

Without the right valves, treatment efficiency drops sharply.

Importance of Proper Valve Selection

Choosing the wrong valve can cause big problems. Here are some things to think about:

- Material compatibility with corrosive or abrasive wastewater

- Flow requirements for high-pressure or low-volume systems

- Longevity to reduce replacement frequency

Choosing the right valves saves energy and protects the environment. They keep systems running well from start to finish.

Understanding the Fundamentals of Butterfly Valves

Butterfly valves are key in wastewater systems, offering simplicity and efficiency. They have a rotating disc that opens and closes in a 90-degree turn. This makes them perfect for butterfly valve benefits in wastewater systems.

These valves are great for tight spaces because they are compact. They fit well in pipelines without taking up too much room.

- Lightweight construction reduces weight load on infrastructure

- Quick shut-off capabilities prevent overflow and leaks

- Cost-effective maintenance compared to alternative valve types

They can handle high flow rates and keep pressure stable. The disc directly touches the seat for a tight seal. This is especially useful in corrosive wastewater.

Regular checks are easy because the disc mechanism allows for easy cleaning. This helps prevent clogs.

Choosing materials like corrosion-resistant coatings boosts durability. For example, EPDM or Viton seals stand up to chemicals found in treatment plants. Their light weight also cuts down on installation costs, needing less labor and support.

When used right, these valves make operations smoother. They have low resistance to flow, saving energy and reducing pump work. This mix of cost-effectiveness and performance makes them a top choice for wastewater management.

Exploring Gate Valves in Wastewater Applications

Gate valves are great for wastewater systems because they can handle high-pressure flows and tough materials. They are built to last in places where corrosion and debris are common. They outperform other valves like butterfly valves in these areas.

Operation and Mechanism

- Linear motion: The gate valve opens fully by lifting a disc straight up, creating an unrestricted flow path.

- Sealing precision: Wedge or parallel discs ensure tight seals when closed, preventing leaks even under pressure.

- Low pressure drop: Full-bore design minimizes turbulence, reducing energy waste during operation.

Design and Key Benefits

| Feature | Benefit |

|---|---|

| Stainless Steel Bodies | Resists corrosion from chemicals in wastewater streams |

| Modular Construction | Easy maintenance and part replacement without full valve removal |

| Bi-directional Flow | Handles fluid movement in any direction without performance loss |

Gate valves excel in wastewater applications where they need to last a long time. Their strong seals and designs for big pipes make them perfect for high-volume treatment facilities.

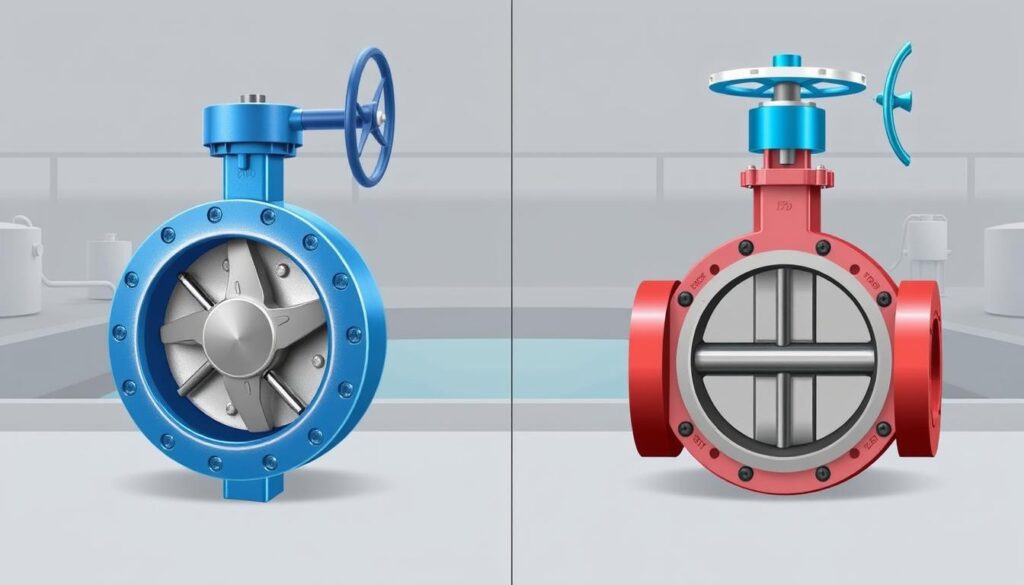

butterfly valves vs gate valves in wastewater

Choosing between butterfly and gate valves depends on system needs. Comparing butterfly and gate valves in wastewater shows their strengths and weaknesses. This helps ensure the best performance in treatment processes.

Performance Comparison

Performance varies with design. Butterfly valves shut off flow quickly but may leak at high pressures. Gate valves provide tight seals under pressure but need more space to operate fully.

- Butterfly: Quick closure, compact size, lower cost.

- Gate: Superior sealing, ideal for high-pressure, precise flow control.

Application Suitability

Applications determine the best choice. Butterfly valves fit tight spaces and moderate-pressure systems. Gate valves are better for heavy-duty wastewater with abrasive materials.

| Criteria | Butterfly Valves | Gate Valves |

|---|---|---|

| Closure Speed | Rapid closure within seconds | Slower, requiring full disk travel |

| Pressure Handling | Up to 150 psi | Up to 300 psi |

| Space Requirements | Compact, fits in tight areas | Requires longer body for full opening/closing |

| Cost | Lower initial investment | Higher upfront cost |

Factors to Consider in Wastewater Valve Selection

Choosing the right valve for wastewater systems is key. It’s about finding a balance between performance and lasting value. Each choice affects how well the system works and its costs over time.

Material and Construction

The material used is crucial for durability in tough wastewater settings. Here are some main options:

- Cast iron: It’s affordable but needs coatings to fight off corrosion

- Stainless steel: It’s tough against wear and chemicals but costs more at first

- HDPE (High-Density Polyethylene): It’s light, doesn’t corrode, and works well for low-pressure systems

| Material | Pros | Cons |

|---|---|---|

| Cast Iron | Cost-effective, sturdy | Risk of corrosion without coatings |

| Stainless Steel | Long lifespan, corrosion resistance | Higher purchase cost |

| HDPE | Chemical resistance, lightweight | Lower pressure capacity |

Cost-Effectiveness

When comparing costs, think about both the upfront price and long-term savings. Consider:

- Installation labor and parts costs

- How long the valve lasts and how often you’ll need to replace it

- Energy savings from efficient valve designs

Maintenance Requirements

Regular maintenance keeps valves running smoothly. Look for valves that are:

- Easy to get to for checks and cleanings

- Designed with parts that wear out less often

- Self-cleaning to avoid clogs

Wastewater Treatment Valves: Benefits and Drawbacks

Choosing the right valve for wastewater systems is key. It’s about finding the right balance. The wastewater valve selection guide helps you make the best choice for your needs.

- Butterfly valves offer quick shut-off and low initial costs.

- Gate valves provide full bore flow paths, reducing pressure loss.

- Both types come in corrosion-resistant materials like ductile iron and stainless steel.

Drawbacks:

- Butterfly valves may struggle with high-pressure wastewater streams.

- Gate valves require more space and time to operate fully.

- Improper material choices can lead to premature corrosion.

“A well-researched selection guide reduces risks by matching valve traits to system needs.”

Regular checks and upkeep can fix many issues. The wastewater valve selection guide also shows how costs add up over time. For instance, gate valves last longer but need more room to install.

By weighing these points, you can make sure your system works well. It should handle debris, chemicals, and flow demands without trouble.

Comparing Efficiency and Performance in Wastewater Systems

When picking between butterfly vs gate valves for sewage treatment, focus on flow control and energy use. Let’s look at how each valve meets wastewater system needs.

Flow Control and Pressure Management

Butterfly valves work well in moderate-pressure settings. They use a rotating disk for quick flow adjustments. Their small size is great for systems needing fast on/off actions.

Gate valves, with their linear gate, offer precise flow control but need more space. They’re better for high-pressure sewage lines because they seal tighter, preventing leaks.

Energy Efficiency Considerations

Energy use differs by valve type. Butterfly valves use less torque, saving energy during partial openings. Gate valves need more power for full strokes but have lower pressure drops once open.

Here’s a quick comparison:

| Factor | Butterfly Valve | Gate Valve |

|---|---|---|

| Flow Adjustment Speed | Fast (quarter-turn operation) | Slower (linear movement) |

| Pressure Resistance | Best for low to medium pressure | Handles high-pressure sewage streams |

| Energy Use | Lower operational energy | Higher initial energy for full stroke |

The choice between these valves depends on your system’s needs. For energy-saving setups with lower pressures, butterfly valves are better. High-pressure systems often choose gate valves for their durability, even if they use more energy.

Innovative Trends in Wastewater Control Valves

In the world of wastewater management, wastewater control valves are at the forefront. They’re moving towards smarter, greener systems. This includes smart sensors and eco-friendly designs. Let’s dive into what’s coming next.

Technological Advancements

Today’s wastewater control valves use IoT and AI. They have sensors that watch flow rates and pressure in real time. This data goes to the cloud, making systems more accurate and less down.

Some big updates include:

- Wireless communication modules for remote monitoring

- Prediction algorithms for maintenance scheduling

- Self-diagnosing valve systems

Sustainability and Eco-Friendly Solutions

Now, makers focus on green materials like corrosion-resistant composites. Brands like A.O. Smith and Pentair use biodegradable coatings. This cuts down on harm to the environment.

Some green features are:

- Recycled polymer components

- Low-emission manufacturing processes

- Energy-efficient designs cutting power use by 30%

These changes don’t just make systems better. They also make them last longer and are kinder to our planet. As rules get stricter, using these new techs helps meet standards and saves money in the long run.

Guidelines for Choosing the Right Valve for Wastewater Systems

When picking the best valves for wastewater, think about performance, durability, and cost. Here’s how to make the right choice:

Selection Criteria Overview

First, look at three important factors:

- Flow requirements: Choose a valve that fits your system’s pressure and fluid type.

- Material compatibility: Stainless steel or ductile iron valves are good against corrosion in tough wastewater.

- Maintenance access

Application-Specific Recommendations

| Scenario | Recommended Valves |

|---|---|

| High-pressure pipelines | Heavy-duty gate valves for tight seals |

| Space-constrained systems | Compact butterfly valves |

| High-solids sewage | Ball valves with full-port designs |

Wastewater Valve Selection Guide

Here’s a simple guide:

- Check your system’s conditions and budget

- Compare valve types using performance charts

- Think about how easy they are to maintain and repair

- Choose based on the total cost over time

Look at products from Watts or Mueller Co. for certified options that meet ANSI standards. Make sure they fit local rules when picking the best valves for wastewater.

Conclusion

Choosing between butterfly or gate valves for wastewater systems depends on project specifics. Butterfly valves save space and cost less. They are great for moderate-pressure applications. Gate valves, with their robust design, suit high-pressure scenarios where full bore flow is critical.

Material selection is key. Butterfly designs with corrosion-resistant coatings work well in abrasive wastewater streams. Gate valves with heavy-duty seals prevent leaks in demanding environments. Maintenance needs also vary—butterfly valves simplify routine checks compared to gate valves’ more involved servicing.

Efficiency and lifecycle costs must guide decisions. Upfront savings from butterfly valves may offset long-term needs. For installations prioritizing durability over space, gate valves remain a trusted option. Evaluating these factors ensures systems meet regulatory standards while balancing performance and budget constraints.

Frequently Asked Questions

What are the main differences between butterfly valves and gate valves in wastewater applications?

Butterfly valves work fast and control flow well, perfect for quick changes. Gate valves are better for fully opening or closing flow but take longer and need more effort.

What are the benefits of using butterfly valves in wastewater systems?

Butterfly valves are light, small, and need little effort to operate. They also control flow well, making them great for big wastewater systems.

What advantages do gate valves provide in wastewater management?

Gate valves last long and seal well, preventing leaks. They’re good for big systems where valves don’t need to be used often.

How do I decide between butterfly and gate valves for sewage treatment?

Think about the job, how much flow you need, and how often you’ll use the valve. Butterfly valves are for control, and gate valves are for blocking off.

What should I look for in a wastewater valve selection guide?

Look for a guide that talks about materials, how they work, pressure, and upkeep. It should also help you find valves that are good value for money.

Can you explain the maintenance requirements for butterfly vs gate valves?

Butterfly valves need little upkeep because they’re simple. Gate valves might need checks on their seals to keep them working right and avoid clogs.

What role do valves play in wastewater treatment efficiency?

Valves are key for controlling flow, managing pressure, and keeping systems working right. The right valves make systems run better and avoid failures, making treatment more efficient.

What innovative trends are emerging in wastewater control valves?

New trends include smart valves that make monitoring easier and eco-friendly options to lessen environmental harm. These advancements aim to improve system control and reduce environmental impact.

How do energy efficiency considerations impact wastewater valve selection?

Energy-saving valves cut costs and carbon emissions. When picking valves, think about their energy use, especially in big wastewater systems.