Have you ever wondered how wastewater treatment facilities effectively manage millions of gallons of waste every day? The key lies in the sophisticated machinery they use, one of the most critical being the centrifugal pump. Understanding how these pumps function and their role in wastewater management enlightens you about the unseen processes keeping our water systems clean.

Introduction to Centrifugal Pumps

What Are Centrifugal Pumps?

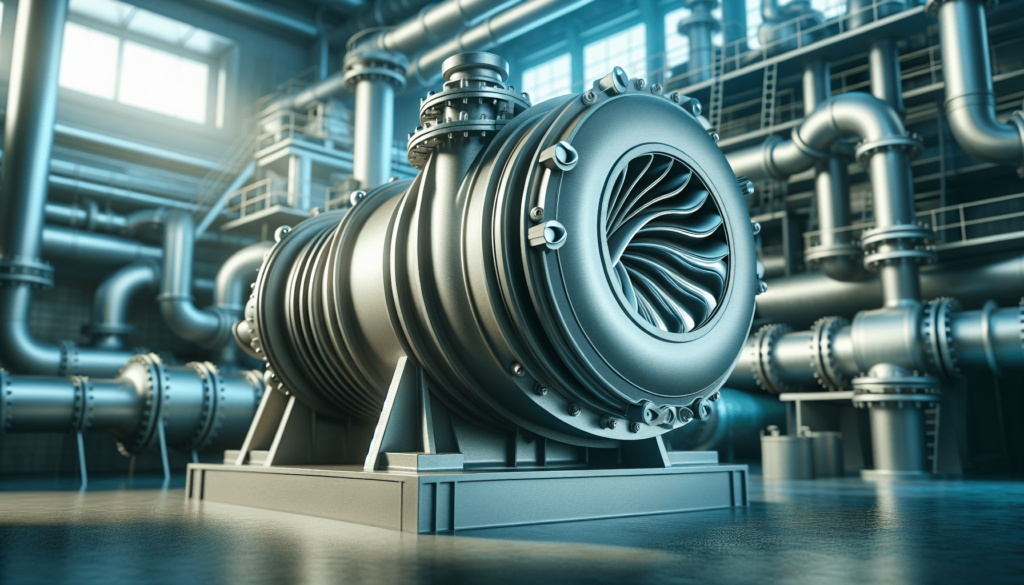

Centrifugal pumps are mechanical devices designed to move liquids through the conversion of rotational kinetic energy to hydrodynamic energy. This transfer is achieved via an impeller—a rotating component that enhances the fluid’s momentum and directs it through the pump casing and out the outlet at a higher pressure. These pumps are commonly used across various industries, from agriculture to pharmaceuticals, given their ability to handle large flow rates and varying degrees of fluid viscosity.

Why Use Centrifugal Pumps in Wastewater Treatment?

In wastewater treatment facilities, managing vast volumes of liquid waste efficiently and reliably is of utmost importance. The centrifugal pump’s design makes it ideal for this purpose as they can handle high flow rates and a variety of fluid properties. Your facility benefits from this versatility because it allows for efficient movement and treatment of municipal sewage, industrial waste, and even stormwater runoff.

Components of a Centrifugal Pump

Understanding the anatomy of a centrifugal pump is essential for comprehending its functionality in wastewater treatment. Here are the main components:

Impeller

The impeller is the heart of the pump, responsible for imparting kinetic energy to the fluid. Its design—consisting of backward-curved blades—enables the conversion of mechanical energy into fluid energy.

Casing

The casing is an airtight chamber that houses the impeller. It channels the accelerated fluid from the impeller into the discharge outlet. Various casing designs, such as volute or diffuser casings, influence efficiency and application.

Shaft and Bearings

The shaft transmits mechanical power from the pump driver (e.g., an electric motor) to the impeller. Bearings support the shaft, minimizing friction and wear and ensuring smooth operation.

Seal and Gaskets

Seals and gaskets prevent fluid leakage while maintaining pressure. In wastewater treatment, selecting the right seal is vital to handling corrosive and abrasive materials.

Operating Principles of Centrifugal Pumps

Kinetic Energy to Hydrodynamic Energy

The core principle is the conversion of kinetic energy, generated by the impeller’s rotation, into hydrodynamic energy needed for fluid movement. As your pump operates, liquid enters the eye of the impeller, and through centrifugal force, it’s pushed outward, gaining speed and pressure before discharge.

Head and Flow Rate

Two critical parameters define pump performance: head (the height a pump can raise fluid) and flow rate (the volume of fluid the pump can move within a given time). These are influenced by the pump’s design and operating conditions, impacting your selection process.

Types of Centrifugal Pumps Used in Wastewater Treatment

Selecting a centrifugal pump type is crucial for addressing specific wastewater challenges and ensuring system efficiency. Let’s explore some common pump types.

Single-Stage and Multi-Stage Pumps

Single-Stage Pumps

Single-stage pumps boast a single impeller, making them straightforward and cost-effective for applications requiring moderate lift and flow.

Multi-Stage Pumps

When higher pressures are needed, such as transferring fluid across long distances or through high-lift applications, multi-stage pumps featuring several impellers in series come into play.

Submersible Pumps

Designed to be submerged in the fluid they pump, these pumps are compact and reduce risk of cavitation, often an issue with suction lift. Submersibles are favorable in scenarios where space is constrained or when dealing with heavily contaminated wastewater.

Self-Priming Pumps

Self-priming centrifugal pumps are a boon when dealing with fluids mixed with air. They eliminate the hassle of manual priming, valuable for systems with occasional dry-run scenarios.

Advantages of Using Centrifugal Pumps in Wastewater Treatment

High Efficiency and Low Maintenance

Centrifugal pumps offer high efficiency with minimal maintenance due to their simple design devoid of complex moving parts. This efficiency translates into energy cost savings and reduced downtime.

Versatility and Flexibility

These pumps can handle a wide variety of fluids, including those with suspended solids, a typical feature in wastewater. If your treatment process demands flexibility, centrifugal pumps provide the ideal solution.

Ease of Operation

Operation is generally straightforward, with easily adjustable flow rates. Their reliable performance makes centrifugal pumps the preferred choice for your wastewater treatment plant’s daily operations.

Challenges and Limitations

No system is without its limitations, and centrifugal pumps are no exception. Being aware of potential challenges helps you prepare better for your plant’s operations.

Cavitation Issues

Cavitation occurs when there are rapid changes in pressure within the pump, leading to bubble formation and implosion. This can cause significant equipment damage over time. Addressing cavitation requires proper system design and pump selection.

Abrasive and Corrosive Fluids

Wastewater often includes abrasive or corrosive substances that can damage pump components. Thorough material selection for pump parts is crucial to combat these effects and prolong pump lifespan.

Air-Entrainment Problems

Pumping fluids containing a significant amount of air is one of the more common issues. Air can cause a drop in pumping efficiency or even complete failure to pump. Self-priming pumps sometimes mitigate this problem.

Practical Tips for Optimizing Centrifugal Pump Performance

Regular Maintenance

Routine inspections and maintenance are pivotal. Ensure impellers are free from debris, bearings are lubricated, and seals are intact. Regular check-ups are essential to extend pump life and maintain performance.

Correct Sizing and Selection

Ensuring your pump is appropriately sized for its intended duties avoids unnecessary energy consumption and wear-and-tear. Matching pump characteristics to system needs is vital for optimum efficiency.

Monitoring and Automation Tools

Modern facilities employ automated monitoring systems. By keeping real-time tabs on parameters like flow rate and pressure, you can swiftly react to anomalies, preventing costly downtime or repairs.

Case Studies of Centrifugal Pumps in Wastewater Treatment

Urban Wastewater Facility

In a busy urban facility, submersible centrifugal pumps were employed to handle varied loads and ensure consistent operations, even during peak hours. Their reliability allowed for reduced manual oversight.

Industrial Waste Management

An industrial plant experienced frequent pump failures due to abrasive substances. After upgrading to corrosion-resistant impellers and casings, downtime reduced significantly, showcasing the importance of material compatibility.

Future Trends and Innovations

Eco-Friendly Designs

As sustainability becomes central, innovations like energy-efficient motors and recyclable components in pump design continue to surface. These green initiatives contribute to the competitive edge of your wastewater treatment operations.

Smart Pump Technology

The future lies in smart pumps with self-diagnostics and predictive maintenance capabilities, enabled by IoT and AI. These systems offer real-time data analysis, further refining operational efficiency.

Conclusion

Embracing centrifugal pumps in wastewater treatment facilities extends beyond their basic functionality. They optimize processes, cut costs, and ensure operational longevity through adaptive technology and improved designs. Understanding their importance and intricacies equips you to make informed decisions for your wastewater management needs. As technology evolves, staying informed on advancements and best practices will maintain your system’s edge and support environmental sustainability.

Additional Resources

Industry Standards & Guidelines

- Hydraulic Institute Standards – Comprehensive pump standards and best practices

- Water Environment Federation (WEF) – Technical resources for wastewater professionals

Technical Documentation

- American Water Works Association – Water industry publications and manuals

- EPA Wastewater Technology Fact Sheets – Government guidelines and specifications

Professional Organizations

- International Water Association – Global network of water professionals

- Pump Systems Matter – Educational resources on pump system optimization

Training & Certification

- Pump Systems Assessment Certification – Professional pump training programs

- WEF Operator Certification – Wastewater operator certifications

Research & Development

- Journal of Water Process Engineering – Latest research in water treatment

- Water Research – Scientific studies in water technology

Note: Please verify all links as they may change over time.