What challenges have you faced while managing your wastewater headworks systems? If you’re in the wastewater treatment industry, you probably know that the headworks represent a crucial element of the system. Troubleshooting these systems can be quite a task. Let’s break down some effective troubleshooting methods to help you identify and resolve issues efficiently.

Understanding Wastewater Headworks Systems

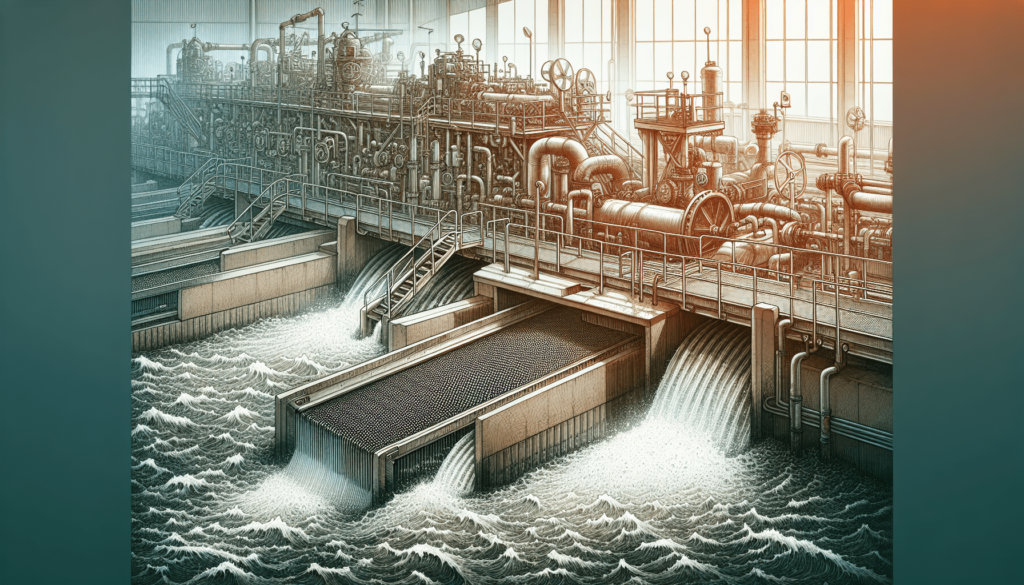

Before jumping into troubleshooting, it’s essential to understand what wastewater headworks systems comprise. These systems are the first step in the treatment process, serving to prepare incoming wastewater for further processing. They typically include screening, flow measurement, grit removal, and primary treatment mechanisms.

By grasping how these components interact, you will be better equipped to diagnose problems when they arise. A strong foundational knowledge of how everything works together will lead to more effective troubleshooting.

Common Issues in Wastewater Headworks Systems

Recognizing common issues can greatly simplify your troubleshooting efforts. Here are a few problems that wastewater headworks systems may encounter:

Clogged Screens

One of the most frequent woes in headworks systems is clogged screens. When debris builds up on the screens, it can impede flow and reduce the efficiency of the entire treatment process. Clogged screens can lead to overflows and other downstream problems if not addressed promptly.

Inconsistent Flow Rates

Another issue you might run into is inconsistent flow rates. If the inflow is too low or too high, it can disrupt the entire treatment cycle, causing strain on other equipment and leading to treatment inefficiencies.

Increased Grit Load

Excessive grit entering the system can cause equipment wear-and-tear and increase operational costs. Monitoring the grit load and addressing its sources can prevent major headaches down the road.

Equipment Failures

Mechanical components frequently wear out over time, leading to unexpected failures. Regular maintenance can help reduce the chances of sudden equipment breakdowns, but it’s still crucial to troubleshoot effectively when issues arise.

Initial Steps in Troubleshooting

When faced with a problem in your wastewater headworks system, it’s best to follow a structured approach to troubleshooting. The initial steps often include:

Inspection

Start with a thorough visual inspection of the system. Look for any obvious signs of trouble, such as overflowing or damaged equipment. Pay special attention to screens, grit chambers, and flow measurement devices.

Reviewing Operational Data

Having records of operational data can be a lifesaver. Review flow rates, maintenance logs, and previous trouble reports to identify patterns or recurring problems. This data can often lead you to the source of the issue.

Engaging the Team

Don’t hesitate to call upon your team for insights. They may have noticed things you haven’t or might have valuable experience that can contribute to resolving the issue at hand. Collaborative problem-solving can often lead you to solutions faster.

Troubleshooting Tools and Techniques

Equipping yourself with the right tools and techniques can make your troubleshooting processes much smoother. Here’s a look at important approaches:

Flow Measurement Tools

Accurate flow measurement is critical. Consider using flow meters to assess how much water is moving through your system at any given time. This can help you identify inconsistencies and blockages.

Video Inspection Systems

If clogged screens or pipes are suspected, video inspection can provide a clear view. This technique allows you to see blockages and structural issues without intrusive and costly methods.

Sound Analysis

Believe it or not, listening to your equipment can provide clues about problems. Unusual sounds—such as grinding, whining, or clanking—can indicate mechanical issues that require your attention. Using noise-analysis tools can help identify these sounds for further examination.

Addressing Specific Issues

Let’s look at how to address each of the common issues mentioned earlier.

Resolving Clogged Screens

- Manual Cleaning: Regular manual cleaning of screens often keeps them functioning well. Make it a part of your preventive maintenance schedule.

- Automated Screen Cleaning Systems: Consider investing in automated systems that can clean screens regularly without human intervention.

- Debris Management Strategies: Implement source control measures to reduce the amount of debris entering your system.

Handling Inconsistent Flow Rates

- Flow Balancing: If inflow rates fluctuate widely, flow balancing techniques may help. Adjust the mechanisms that control the inflow to achieve a more stable rate.

- Operational Adjustments: Depending on your findings from operational data, you may need to modify how you manage system parameters, such as pump speed or volume control.

Managing Grit Load

- Grit Removal Systems: Installing effective grit removal systems can help mitigate excessive grit entering your headworks.

- Routine Monitoring: Keep a close eye on grit levels and check for sources that contribute to excessive grit production to avoid bigger issues later.

Mitigating Equipment Failures

- Regular Maintenance: Establish a rigorous maintenance schedule for all equipment within the headworks. Regular checks can prevent mechanical failures.

- Immediate Diagnosis: When equipment does fail, engaging in swift diagnosis can help limit downtime. Have processes in place to quickly troubleshoot and repair equipment.

Implementing Preventive Measures

Once you have effectively troubleshot the present issues in your wastewater headworks systems, you should implement preventive measures to ensure they don’t reoccur. Here are some strategies to consider:

Routine Maintenance Schedule

Drafting a routine maintenance schedule ensures critical components receive regular inspections. This could include checking screens, grit-removal systems, and flow meters on a weekly or monthly basis, depending on the system’s needs.

Staff Training

Increasing your team’s knowledge is invaluable. Offering training sessions on system components and troubleshooting methods can empower them to identify and solve issues swiftly.

System Upgrades

Sometimes, simply upgrading parts of your system can create more streamlined processes. Technological advancements, such as smart sensors for flow monitoring, can greatly aid in maintaining consistent operation.

Documenting Troubleshooting Efforts

Documentation plays a critical role in troubleshooting. Keeping records of what problems occurred, the steps taken to resolve them, and the results will help you in the long run. Here’s why it matters:

Knowledge Base

By tracking problems and solutions, you create a valuable knowledge base. This resource can be beneficial for current and future team members.

Identifying Patterns

Long-term records can help identify trends in your system. If certain issues reoccur, you can address the root cause rather than only treating symptoms.

Compliance and Reporting

For regulatory and compliance reasons, maintaining thorough records of system troubles and resolutions is essential. Being able to report effectively on your operations can assist with audits and inspections.

Conclusion

Troubleshooting wastewater headworks systems can be a daunting task, but with the right tools, techniques, and knowledge, you can navigate these challenges effectively. Understanding common issues and having a structured approach, such as diligent inspections, engaging your team, and utilizing specialized tools, can significantly enhance your operation.

Implementing preventive measures and documenting troubleshooting efforts ensures you’re well-prepared for any future challenges that come your way. As you face the day-to-day realities of managing wastewater systems, rest assured that the right strategies and a proactive mindset will guide you toward success. Stay committed to learning and adapting, and you’ll always be one step ahead in ensuring efficient wastewater treatment.