Have you ever wondered about the complexities involved in wastewater treatment, particularly the process of nitrification? It’s a fascinating and essential aspect of ensuring that treated water is safe for release into the environment. Understanding the intricacies of wastewater nitrification, the issues that could arise, and effective solutions can be pivotal for professionals in the field. This guide aims to shed light on these aspects systematically, helping you navigate common problems and their resolutions.

Introduction to Nitrification in Wastewater Treatment

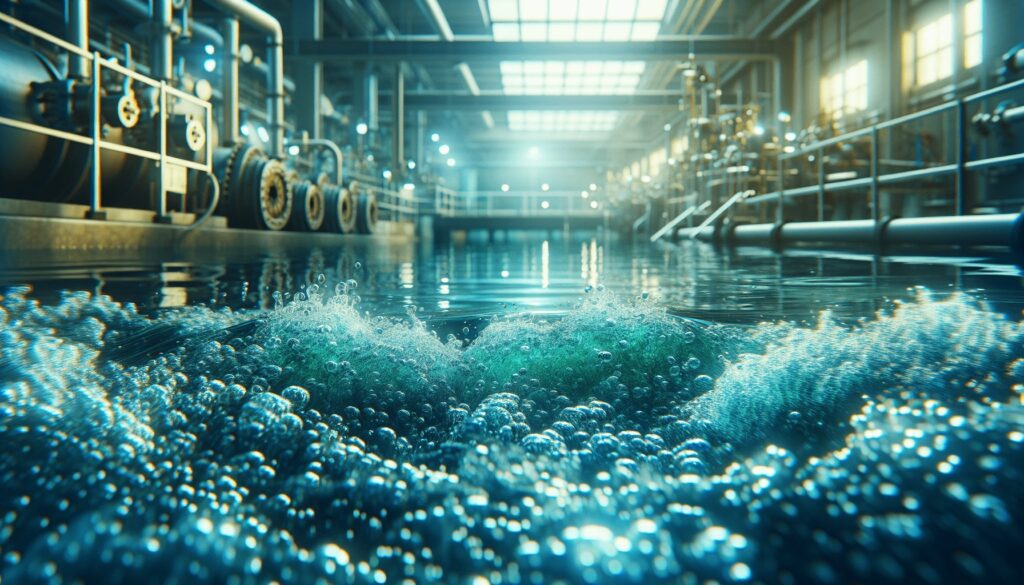

Nitrification is a biochemical process integral to wastewater treatment involving the conversion of ammonia into nitrites and then nitrates. This process is crucial as it mitigates the toxicity of ammonia to aquatic life and contributes to the overall nitrogen removal from wastewater.

The Role of Ammonia-Oxidizing and Nitrite-Oxidizing Bacteria

The nitrification process is primarily driven by two groups of bacteria: ammonia-oxidizing bacteria (AOB) and nitrite-oxidizing bacteria (NOB). AOB kickstart the process by converting ammonia (NH3) into nitrite (NO2-), while NOB take over by converting nitrite into nitrate (NO3-). This step-wise conversion is vital for reducing the nitrogen load in wastewater and minimizing its environmental impact.

Impacts of Proper and Improper Nitrification

Achieving optimal nitrification in waste treatment not only ensures the reduction of harmful nitrogen compounds but also improves the overall quality of the effluent. In contrast, improper nitrification can lead to elevated levels of ammonia or nitrite, potentially resulting in toxic discharges that harm aquatic ecosystems and disrupt water bodies.

Common Nitrification Issues in Wastewater Treatment

Nitrification is not immune to complications, and several issues might arise during treatment. Recognizing these issues early is crucial in addressing them effectively.

Incomplete Nitrification

Incomplete nitrification occurs when ammonia is not fully converted into nitrate. This can be symptomatic of insufficient bacteria or other system deficiencies, leaving harmful levels of ammonia in the treated water.

Nitrification Inhibition

Another common issue is nitrification inhibition, where environmental or chemical factors suppress the activity of AOB and NOB, slowing down or halting the conversion process. This might be due to the presence of toxic substances, unfavorable pH, or temperature extremes.

Nitrifier Washout

Nitrifier washout happens when the bacterial population involved in nitrification is flushed out of the system, often because of improper sludge management or hydraulic overloading.

pH Imbalance and Nitrite Lock

A balance in pH is critical for nitrification. Deviations can inhibit bacteria activity, causing issues like nitrite lock, where nitrite accumulation occurs due to the halt in conversion to nitrate.

Troubleshooting Nitrification Problems

Identifying and troubleshooting nitrification problems involve a series of investigative steps.

Assessing Dissolved Oxygen (DO) Levels

Adequate DO is essential for the nitrification process. Frequent checks can help ensure that the levels are conducive to bacterial activity.

Temperature Considerations

Temperature influences bacterial growth rates. Regular monitoring can alert you to any deviations that might necessitate adjustments to maintain optimal bacterial performance.

Balancing pH and Alkalinity

Maintaining a healthy pH range through alkalinity control is vital for sustaining nitrification. Testing kits or automated systems can assist in ensuring these parameters remain stable.

Toxicity Testing

Identifying any toxic substances that might be disrupting the bacterial processes is also part of effective troubleshooting. This might involve specialized assays to detect inhibitory substances.

Managing Sludge Retention Time (SRT)

Proper SRT management ensures a stable population of nitrifying bacteria, preventing issues like washout and maintaining treatment efficacy.

Solutions to Common Nitrification Issues

Once an understanding of the problems is established, implementing practical solutions becomes the next logical step.

Increasing Aeration

Boosting aeration can help maintain DO levels within the desired range, providing a conducive environment for bacterial activity.

Chemical Additions for Alkalinity and pH Control

When natural balancing is not enough, chemical additions might be required to adjust alkalinity and pH, ensuring the nitrification process proceeds smoothly.

Temperature Management

Insulating facilities or adjusting operational hours can help mitigate temperature extremes, maintaining an environment that supports bacterial health.

Modifying Sludge Retention Time (SRT)

Adjusting SRT by changing sludge wasting rates helps maintain a balanced and thriving microbial community essential for ongoing nitrification.

Strategies for Nitrite Removal and Toxicity Control

Implementing strategies to remove excess nitrite, perhaps via bioaugmentation, and controlling toxic load by identifying and eliminating sources can significantly enhance treatment outcomes.

Monitoring and Long-Term Solutions for Stable Nitrification

Long-term stability in nitrification processes requires vigilant monitoring and proactive management.

Regular Monitoring of Key Parameters

Frequent testing of critical parameters such as ammonia, nitrite, nitrate, DO, pH, and alkalinity is crucial. Automated systems can assist by providing real-time data for prompt decision-making.

Process Control Strategies

Developing robust process control strategies and adopting predictive modeling can help anticipate issues before they become significant problems.

Staff Training and Automated Systems

Ongoing training for staff ensures they are equipped with the latest knowledge and strategies for maintaining stable nitrification. Integrating automated systems further supports consistent process oversight.

Case Studies of Successful Nitrification Troubleshooting

Real-world examples offer valuable insights into problem-solving in wastewater treatment.

Low DO Levels

In one case study, a plant tackled low DO levels by recalibrating aeration systems, leading to restored nitrification efficiency and reduced ammonia levels in effluent.

Toxic Discharges

Another facility identified and eliminated a source of chemical contamination, which had been inhibiting bacterial activity, resulting in improved treatment performance.

Nitrite Accumulation in Cold Weather

An example from a northern region demonstrated the adaptation of temperature management strategies during winter months to prevent nitrite accumulation, maintaining treatment efficacy year-round.

Conclusion

Your understanding of nitrification issues and solutions in wastewater treatment underpins the effectiveness and ecological responsibility of treatment operations. By emphasizing regular monitoring, troubleshooting, and maintenance, you can minimize risks and optimize nitrogen removal processes. Consistent training and adoption of technology play pivotal roles in preventing potential problems and ensuring the water released back into the environment is safe and clean. As you refine these practices, remember that proactive and informed actions are key to successful wastewater management.

Resources

Here are some valuable resources for understanding and addressing wastewater nitrification issues:

- EPA: Nitrogen Control in Wastewater Treatment

- Learn more about nitrogen control and nitrification from the U.S. Environmental Protection Agency (EPA).

- Visit EPA’s Nitrogen Control Resource

- Water Environment Federation (WEF): Nitrification in Wastewater

- WEF provides comprehensive resources on nitrification processes and operational troubleshooting.

- Explore WEF’s Nitrification Resources

- United States Geological Survey (USGS): Nitrogen Cycle Overview

- Understand the nitrogen cycle and its implications for water treatment from the USGS.

- Learn More on the Nitrogen Cycle

- National Environmental Services Center (NESC): Wastewater Nitrification Guide

- NESC offers helpful guides and fact sheets on nitrification and other wastewater treatment processes.

- Access NESC’s Wastewater Resources

- Environmental Science & Engineering Magazine (ESEMAG): Troubleshooting Nitrification

- Explore industry insights and best practices for troubleshooting nitrification issues in wastewater.

- Read ESEMAG’s Troubleshooting Guide

These resources provide practical insights and technical guidance to support effective nitrification management in wastewater treatment.