Have you ever wondered how wastewater treatment facilities manage the mountain of sludge they handle every day? Effective sludge management is crucial for these facilities, ensuring that waste is treated in a way that is environmentally safe and economically viable. One of the traditional yet effective methods employed in wastewater treatment plants is the use of sludge drying beds. Though simple, these systems hold significant importance, especially for smaller operations. Let’s unravel the intricacies of sludge drying beds and understand their vital role in the wastewater treatment process.

Introduction

In the realm of wastewater management, effective sludge handling is paramount. Sludge, the semi-solid byproduct from wastewater treatment, must be managed to prevent environmental hazards and promote sustainability. Efficient dewatering is essential, as it reduces sludge volume and makes disposal more manageable. Sludge drying beds, as an age-old method of handling this challenge, present a balance of simplicity and effectiveness, particularly suited for small to medium-sized facilities. Their design allows for practical dewatering without the need for complex machinery, making them a cornerstone in many wastewater operations.

What are Sludge Drying Beds?

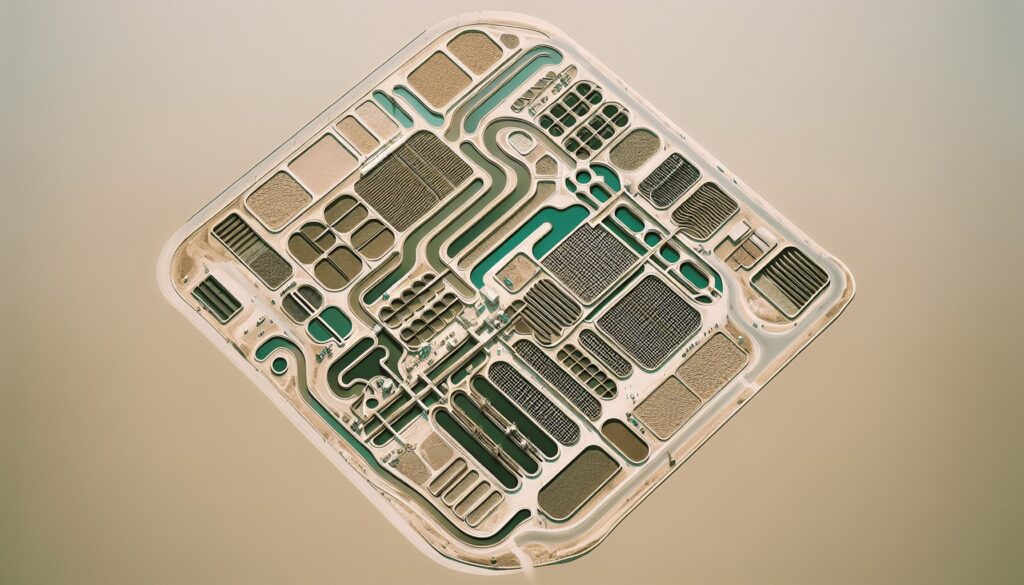

Sludge drying beds are engineered structures designed to dewater sludge through natural means such as drainage and evaporation. Typically, a sludge drying bed consists of several well-defined layers. At the bottom, there’s a filter layer usually composed of gravel and sand, which aids in drainage. Above this layer lies the sludge, which becomes dewatered as excess moisture filters through the substrate.

There are several designs available, often differentiated by the type of covering used. Open beds rely entirely on environmental factors, while covered beds offer some protection against adverse weather, enhancing efficiency. The layout and operation are tailored to promote effective water removal, making these beds versatile for various sludge types and environmental conditions.

How Sludge Drying Beds Work

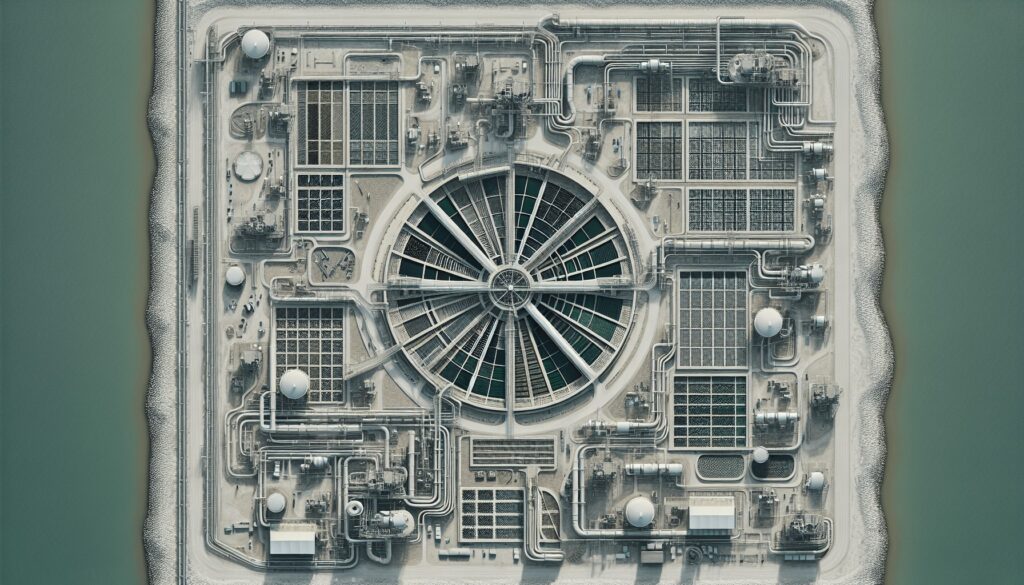

The operation of sludge drying beds revolves around two primary processes: gravity drainage and evaporation. Once the sludge is placed on the beds, gravity helps draw moisture out of the sludge and through the underlying layers. As the water percolates down, an underdrain system collects and redirects it away from the dried material. Meanwhile, evaporation, driven by factors such as sunlight, temperature, and wind, further aids in moisture reduction.

The environmental conditions play a critical role here. Higher temperatures, ample sunlight, and breezy conditions enhance evaporation rates, facilitating quicker drying. The role of climate cannot be understated when considering the performance of sludge drying beds, as different weather patterns can significantly affect the speed and efficiency of dewatering.

Types of Sludge Drying Beds

With multiple designs to choose from, let’s explore the varied types of sludge drying beds to understand their unique benefits and features.

Conventional Sludge Drying Beds

The most traditional version, conventional sludge drying beds, rely fully on natural processes. With their open-top design, these beds depend entirely on favorable weather conditions for drying, making them cost-effective and straightforward but somewhat weather-dependent.

Covered Sludge Drying Beds

Covered beds introduce a protective layer over the sludge bed to shield it from rain and excessive wind, stabilizing the drying process. This covering can improve efficiency by maintaining a more consistent environment, albeit at a higher initial installation cost.

Artificially Heated Sludge Drying Beds

In colder climates or regions with less sunshine, artificially heated beds become invaluable. By integrating heating systems, these beds offer controlled and rapid dewatering, allowing for year-round operation. The added energy requirements, however, may increase operational costs.

Vacuum-Assisted Sludge Drying Beds

A more advanced design, vacuum-assisted beds enhance drying by applying a vacuum to the drainage process. This method significantly accelerates dewatering, reducing sludge moisture content much faster than natural evaporation can achieve. These are especially useful in situations where time is a crucial factor.

Here’s a brief comparison to outline the distinctions:

| Type | Key Features | Advantages | Limitations |

|---|---|---|---|

| Conventional | Open-top design, relies on natural processes | Low cost, simple | Weather-dependent |

| Covered | Protective covering | Stability in drying, weather-resistant | Higher installation cost |

| Artificially Heated | Integrated heating | Rapid and controlled drying | Higher energy cost |

| Vacuum-Assisted | Utilizes vacuum pressure | Fast dewatering | Complex, costlier setup |

Benefits of Sludge Drying Beds

The advantages offered by sludge drying beds make them an attractive option for smaller and rural facilities. Primarily, they are cost-effective, avoiding the need for expensive machinery or high energy consumption. Their simple design makes them easy to construct and operate, requiring minimal technical skills for maintenance and everyday use.

Furthermore, the dried sludge produced is often of high quality and can be either disposed of safely or used as a beneficial byproduct, such as for composting or land application. These factors together underscore the suitability of sludge drying beds for those looking to balance effectiveness with budgetary constraints.

Limitations and Challenges

Even with their numerous benefits, sludge drying beds come with challenges that operators must address. Slow drying times can occur in unfavorable weather, significantly hampering efficiency. Additionally, these systems require a large physical footprint, potentially limiting their implementation in space-constrained facilities.

Odor control and vector attraction, which refers to the attraction of pests, can pose significant issues, particularly in less urbanized settings. Seasonal factors can also influence performance, creating the need for operators to adapt their approaches in response to changing conditions. Addressing these challenges involves thoughtful planning and might include enhancements like coverings or hybrid systems to mitigate climatic impacts.

Sludge Drying Bed Operation and Maintenance

Operating sludge drying beds involves a series of routine tasks that ensure their continued effectiveness. A key element is regular sludge application, ensuring an adequate amount is spread for optimal drying. Monitoring the process helps detect issues like uneven drying, while the removal of dried sludge prevents any backlog.

Maintenance involves several procedures, such as cleaning the bed surface, replenishing sand layers when necessary, and inspecting the underdrain system to ensure unobstructed flow. Common operational problems, like clogged drains, can be addressed with regular maintenance schedules and timely interventions.

Comparisons with Other Dewatering Methods

When evaluating sludge drying beds in comparison to other methods, flexibility, cost, and energy usage stand out as significant differentiators. Mechanical methods, such as centrifuges or belt presses, often provide rapid results and are suitable for larger facilities dealing with vast sludge volumes. However, these methods come with higher costs and energy demands.

Sludge drying beds, while slower, offer an economic and environmentally friendly choice for smaller operations. Each method caters to different needs, making it essential for facilities to assess their particular context and capacity requirements when choosing the most suitable approach.

Conclusion

In the landscape of wastewater management, sludge drying beds stand out for their balance of cost-effectiveness and operational simplicity. Particularly beneficial for smaller facilities, these systems provide a reliable alternative to more complex dewatering methods. Despite certain limitations, like weather dependency and space requirements, their ability to deliver energy-efficient dewatering solutions remains unmatched. As you continue to think about the future of wastewater treatment, the role of sludge drying beds in sustainable and practical sludge management is likely to hold enduring relevance.