Have you ever heard about cavitation in wastewater operations and wondered what it truly entails? You’re not alone in your curiosity. Cavitation is a fascinating phenomenon that significantly impacts the effectiveness and longevity of machinery used in wastewater treatment. By understanding cavitation, you can better grasp how this invisible force can affect the systems you rely on.

What is Cavitation?

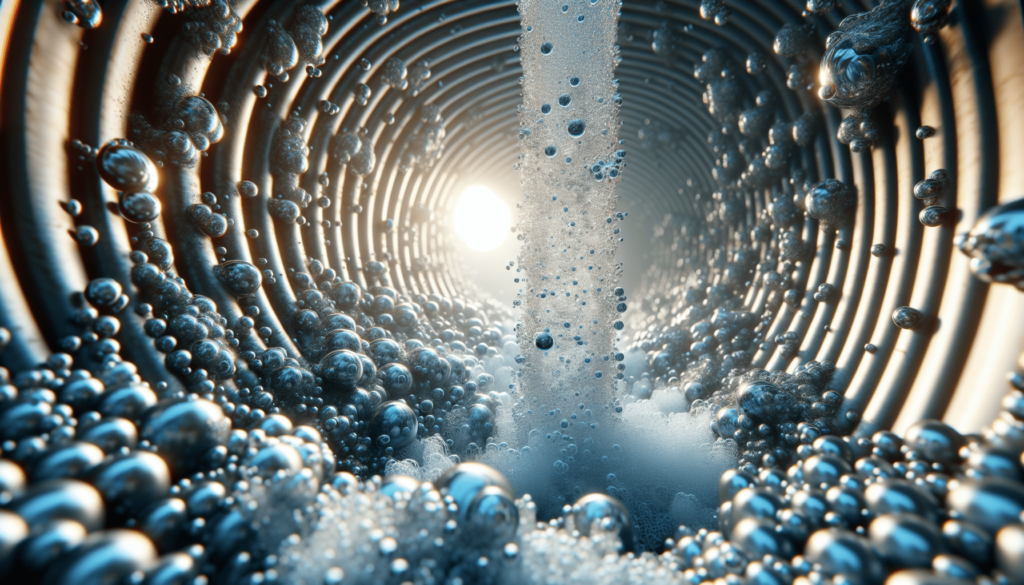

Cavitation refers to the formation and immediate collapse of vapor bubbles in a liquid. This process occurs when a liquid is subjected to rapidly changing pressure conditions. For those involved in wastewater operations, the consequences of cavitation are crucial to understand.

Causes of Cavitation

The primary cause of cavitation is the change in pressure experienced by a liquid. When pressure in a liquid falls below its vapor pressure, small bubbles or cavities form. Once these bubbles travel to areas of higher pressure, they collapse. Imagine these as tiny implosions taking place within the liquid, and that is cavitation at its essence.

Types of Cavitation

Understanding that cavitation can manifest in different forms is essential for recognizing how it might affect your systems. Here’s a look at the primary types:

- Hydrodynamic Cavitation: Occurs when liquid speeds increase rapidly, reducing the pressure beneath its vapor pressure. This type is common in pumps and pipelines.

- Acoustic Cavitation: Triggered by sound waves; happens less frequently in wastewater applications but is notable in ultrasonic cleaning devices.

- Vortex Cavitation: Occurs in systems with swirling fluids like certain impeller designs.

- Rotational Cavitation: Happens in rotating devices where centrifugal forces are significant.

Each type introduces its own challenges and potential areas of failure for wastewater operators to consider.

Impact of Cavitation on Wastewater Operations

Cavitation can cause a range of issues that affect the functionality and durability of wastewater systems.

Damage to Equipment

The collapse of vapor bubbles can produce intense shock waves. These incur wear and tear on machinery, leading to:

- Pitting: Surface wear resulting from the impact of the bubbles.

- Material Erosion: Gradual degradation of materials, especially in vulnerable components like pump impellers.

Long-term exposure to cavitation can therefore shorten equipment lifespan, leading to increased maintenance costs and unscheduled downtimes.

Efficiency Loss

Apart from physical damage, cavitation can lead to efficiency problems. The collapse of bubbles disrupts smooth fluid flow, causing fluctuations in pressure and flow rates. Lower efficiency in pumps and other devices means reduced overall performance in wastewater treatment and higher energy costs.

Recognizing Cavitation Symptoms

Identifying signs of cavitation early can save you from costly repairs and operational delays.

Audible Indicators

Cavitation often produces a distinct noise, often described as gravel or rocks being churned inside equipment. If you hear such noises emanating from pumps or pipes, it’s time to investigate further.

Performance Indicators

If efficiency drops suddenly or if you notice inconsistent flows, cavitation may be the culprit. Monitoring equipment performance metrics regularly can help to identify when cavitation might be occurring.

Visual Examination

Upon inspection, signs such as surface pitting or unusual wear patterns on machinery components can indicate cavitation.

Preventing Cavitation

Prevention is always better than cure, and with cavitation, there are several strategies you can implement to safeguard your operations.

Proper System Design

Proper design is key to reducing the risk of cavitation. Ensure that systems are designed with:

- Correct pump sizing to handle expected flows without exceeding recommended operating conditions.

- Adequate pipe sizing and alignment to prevent sudden changes in velocity and pressure.

Regular Maintenance

Routine maintenance can help identify early signs of cavitation. Keep an eye on pump seals, bearings, and impellers for any signs of damage. Immediate attention to such signs can prevent more severe damage.

Monitoring Systems

By implementing robust monitoring systems that focus on pressure and flow rate data, you can detect unusual changes that might suggest cavitation.

Use of Anti-Cavitation Devices

Using anti-cavitation devices or specially designed components such as venturi tubes and diffusers can help manage pressure variances within systems, minimizing cavitation risks.

Addressing Cavitation in Existing Systems

Suppose cavitation has already been identified. In that case, several approaches can be taken to mitigate its effects and prevent future occurrences.

Cavitation-Resistant Materials

Incorporating materials that withstand the vigorous impacts of collapsing bubbles can extend equipment longevity.

System Adjustments

Modifying operational parameters, such as adjusting pump speed or reconfiguring piping layouts, can reduce cavitation occurrences.

Retrofits and Upgrades

Investing in modern technologies or upgraded components resistant to cavitation might involve initial costs but ultimately saves money by preventing repairs and maintaining system efficiency.

Importance of Dealing with Cavitation

Ignoring cavitation not only harms your equipment but can compromise the entire wastewater treatment process.

Environmental Impact

Efficient wastewater systems are critical for maintaining environmental health. Cavitation-induced failures can lead to untreated or improperly treated wastewater being released, posing significant environmental hazards.

Financial Considerations

As equipment underperforms or fails due to cavitation, operational costs rise. From increased energy consumption to frequent repairs or replacements, the financial implications are substantial.

Regulatory Compliance

Meeting industry regulations requires consistent performance levels. Cavitation-induced inefficiencies or breakdowns could jeopardize compliance, leading to penalties and reputation damage.

Future Perspectives

Given the potential impacts, advancing technologies to combat cavitation in wastewater operations is crucial.

Smart Monitoring Technologies

The rise of IoT and smart monitoring technologies offers promising avenues to detect cavitation early. These tools offer real-time insights into system health and allow quick interventions.

Advanced Material Science

Emerging materials with enhanced durability against cavitation effects are continuing to evolve, promising better resistance and longer lifespans for equipment.

Innovative Design Practices

Engineers and designers are continually developing new strategies to minimize cavitation through innovative system designs and pump technologies.

Conclusion

Understanding cavitation is vital for anyone involved in wastewater operations. By recognizing its causes and effects, and implementing preventive and mitigation strategies, you can maintain efficient and sustainable systems. Taking proactive measures ultimately helps safeguard not just your operations but also the surrounding environment. As technology evolves, continue staying informed and adaptive to minimize cavitation’s impact effectively.