Have you ever wondered how wastewater treatment facilities manage the delicate balance between food for microorganisms and the microorganisms themselves? This balance is crucial in determining the effectiveness and efficiency of the treatment process. It’s all thanks to a concept known as the Food to Microorganism (F/M) ratio, a term that’s vital in understanding both Membrane Bioreactors (MBR) and conventional wastewater treatment systems.

What is the F/M Ratio?

The Food to Microorganism (F/M) ratio is a critical concept in wastewater treatment that reflects the balance between the amount of organic matter (food) available and the microorganism concentration in the system. It’s expressed as a ratio of substrate mass (food) to the biomass concentration (microorganisms) in the treatment process. This ratio provides insight into the operational conditions of a biological treatment system, influencing both the efficiency of organic matter removal and the stability of the microbial community.

Importance of the F/M Ratio

Why is this ratio so important, you ask? The F/M ratio affects the rate of organic matter decomposition, the growth rate of microorganisms, and the efficiency of nutrient removal. Keeping this ratio within an optimal range ensures that the microorganisms have enough food to thrive and break down pollutants effectively without overwhelming the system.

Understanding Membrane Bioreactors (MBR)

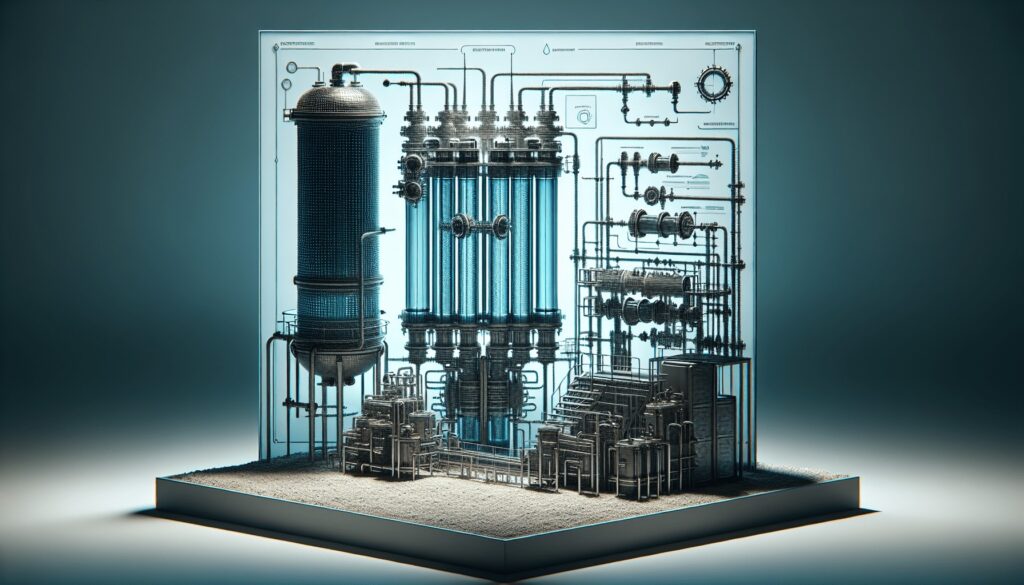

Before diving into how the F/M ratio applies, it’s helpful to know what a Membrane Bioreactor is. An MBR is an advanced wastewater treatment process that combines biological treatment with membrane filtration. This hybrid system harnesses the power of microorganisms to degrade pollutants and uses membranes to separate out treated water from sludge.

Components of MBRs

An MBR system consists of two main components: a biological reactor where the biological decomposition takes place, and a membrane unit where the treated water is separated. The membrane unit can be either immersed in the biological reactor or located externally.

How MBRs Work

In MBRs, wastewater undergoes biological treatment in the reactor, where microorganisms consume organic matter. Then, the membrane acts as a physical barrier, preventing microorganisms and other solids from passing through, which results in a clear effluent. This process not only improves the quality of the treated water but also allows for more compact treatment facilities.

Conventional Wastewater Treatment Systems

Conventional systems, often known as activated sludge processes, are the traditional method of treating wastewater. These systems also rely on microorganisms but differ significantly in design and operation from MBRs.

Components of Conventional Systems

A typical conventional system includes a biological reactor, similar to MBRs, but features a settling tank for separating solids from treated water rather than a membrane. Solids separate out by gravity, which is less efficient compared to membrane filtration.

How Conventional Systems Work

In these systems, the wastewater is mixed with recycled activated sludge in the biological reactor. After sufficient contact time, the mixture overflows into the settling tank where gravity separates the solids from the treated water. Given this method’s reliance on gravity and larger physical footprint, its effluent is generally not as clear as MBR-treated effluent.

Differences Between MBRs and Conventional Systems

Having grasped the basic workings of both MBRs and conventional systems, it’s time to explore how they differ, particularly regarding the F/M ratio.

Efficiency in Handling Organics

MBRs are generally more efficient at handling high organic loads compared to conventional systems due to the membrane filtration step. This efficiency often allows for operating at lower F/M ratios, which can lead to more stable microbial communities and effective pollutant removal.

Impact on F/M Ratio

The closed nature of MBRs permits tighter control of the F/M ratio, benefiting from higher biomass concentrations. This higher concentration leads to lower F/M ratios. In contrast, conventional systems may require higher F/M ratios as the biomass content is generally lower and less controlled.

Sludge Retention and Quality

MBRs facilitate extensive sludge age due to their higher retention of biomass, which means biomass can be retained for longer periods without loss. This retention improves sludge quality and reduces its production. On the other hand, sludge quality and retention in conventional systems are more affected by operational changes, such as the solids retention time and hydraulic retention time, and typically result in higher volumes of sludge that must be managed or disposed of.

Optimizing the F/M Ratio in MBRs

Operating an MBR requires careful management of the F/M ratio to maximize system efficiency and effluent quality.

Managing Biomass Concentration

To optimize the F/M ratio, the biomass concentration should be adjusted regularly. This management ensures that there are sufficient microorganisms present to metabolize incoming organic matter without exhausting their food supply.

Adjusting Feed Rates

Changes in the influent load should be matched by adjustments in the feed rate to the biological reactor. Sudden increases in organic load require careful observation to prevent the F/M ratio from rising too high and overwhelming the microbial population.

Regular Monitoring

Due to the sophisticated nature of MBRs, regular monitoring and analytical measurements are required. Utilizing tools like sensors to measure parameters such as suspended solids, dissolved oxygen, and organic load helps maintain optimal F/M ratios and system performance.

Advantages of MBRs in Controlling F/M Ratios

MBRs offer several advantages, particularly in their ability to maintain a low and stable F/M ratio.

Increase in System Stability

The lower F/M ratio in MBRs tends to result in more stable microbial communities, leading to steady process performance over time. This stability is essential for maintaining consistent effluent quality and system resilience against load variations.

Compact Treatment Plants

Due to the ability to maintain higher biomass concentrations and operate at lower F/M ratios, MBRs allow for more compact treatment processes compared to conventional systems. This compactness not only saves space but also facilitates easier retrofitting into existing facilities.

Enhanced Effluent Quality

The combination of biological treatment with membrane filtration leads to improved effluent quality, with MBRs typically producing clearer and higher-quality treated water compared to conventional processes.

Challenges in Managing F/M Ratios in Conventional Systems

Operating conventional systems presents its challenges, especially in achieving the desired F/M ratio.

Sensitivity to Operational Changes

Conventional systems are often more sensitive to fluctuations in influent load and composition, which can readily alter the F/M ratio. These changes necessitate frequent process adjustments to maintain treatment quality.

Sludge Production

Higher F/M ratios in conventional systems can result in increased sludge production, leading to more frequent waste sludge handling and associated operational costs.

Comparing MBR and Conventional Systems: A Snapshot

To wrap up, let’s look at a summary of differences between MBRs and conventional systems relating to the F/M ratio:

| Characteristic | MBR | Conventional System |

|---|---|---|

| F/M Ratio | Lower, stable | Higher, more variable |

| Biomass Retention | High | Moderate |

| Sludge Production | Lower | Higher |

| System Footprint | Compact | Larger |

| Effluent Quality | Superior | Adequate |

Conclusion

Understanding the F/M ratio is key to appreciating the differences between Membrane Bioreactors and conventional wastewater treatment systems. MBRs excel with their ability to maintain low F/M ratios, promoting high system stability and superior effluent quality in a compact setup. Conventional systems, while tried and tested, face challenges in handling increased sludge production and maintaining consistent treatment performance amid fluctuations in influent characteristics.

Grasping the intricacies of these systems allows you to appreciate the advancements in wastewater treatment technology, ensuring both environmental protection and resource efficiency. Each model has its unique strengths and challenges, and the decision to employ one over the other often depends on specific treatment goals, load characteristics, and available resources.