Have you ever wondered how industries efficiently manage sludge treatment? The answer lies in a crucial piece of equipment known as an industrial belt filter press. This device plays a vital role in separating solids from liquids, making it an indispensable asset in various industrial processes.

A belt filter press operates by combining gravity drainage and mechanical pressure to achieve effective sludge treatment. This not only enhances the efficiency of the treatment process but also reduces the volume of waste, making it easier to handle and dispose of.

Key Takeaways

- Efficient sludge treatment through solid-liquid separation.

- Combination of gravity drainage and mechanical pressure.

- Reduces waste volume for easier disposal.

- Enhances overall treatment process efficiency.

- Crucial in various industrial applications.

What Is a Belt Filter Press?

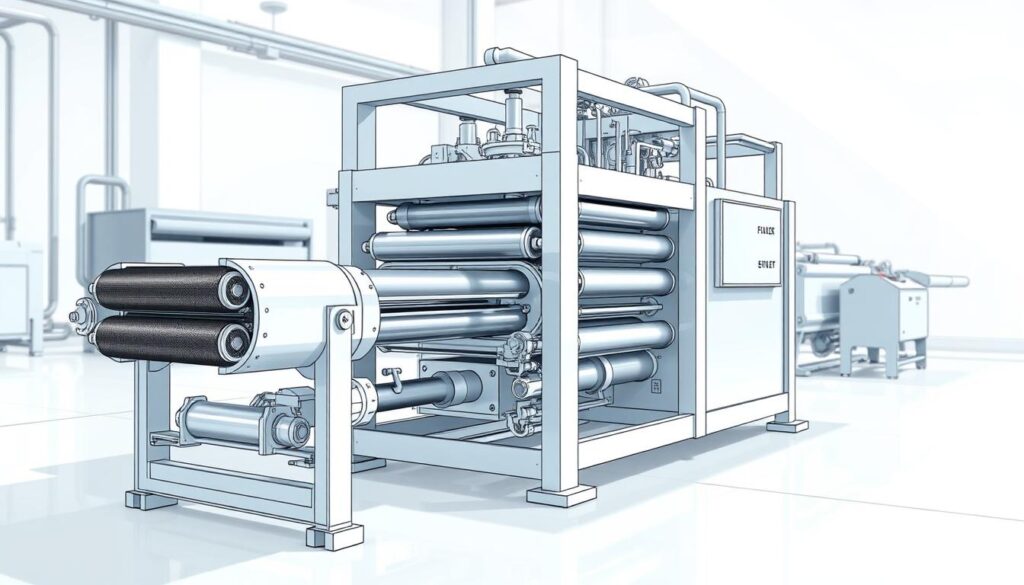

The belt filter press is a device used for the mechanical dewatering of sludge through the combination of filter belts and mechanical pressure. Its workflow includes several key stages: sludge feeding, gravity dewatering, wedge dewatering, and squeeze dewatering.

Definition and Purpose

A belt filter press is defined as equipment that utilizes a combination of filter belts and rollers to dewater sludge. Its primary purpose is to reduce the volume of sludge, making it easier to handle and dispose of. According to a source, “a belt filter press is equipment for mechanical dewatering of sludge through the combination of filter belt and drum.”

The belt filter press operation involves feeding sludge onto the filter belt, where it undergoes various stages of dewatering. The design of the belt filter press allows for efficient removal of water from the sludge, resulting in a drier cake.

Historical Development and Evolution

The belt filter press has undergone significant developments since its inception. Initially used in industrial applications, it has evolved to become a crucial component in wastewater treatment processes. Over time, advancements in belt filter press design have improved its efficiency and effectiveness.

Historically, the belt filter press was designed to handle large volumes of sludge. As technology advanced, so did the design and functionality of belt filter presses, enabling them to be used in various industries.

| Feature | Description | Benefit |

|---|---|---|

| Filter Belts | Used for filtering sludge | Efficient dewatering |

| Rollers | Apply mechanical pressure | Effective sludge volume reduction |

| Dewatering Stages | Gravity, wedge, and squeeze dewatering | Produces dry cake |

The Fundamental Science Behind Solid-Liquid Separation

Understanding the science that governs solid-liquid separation is essential for optimizing belt filter press performance. The process involves several key principles that work together to achieve efficient dewatering.

Filtration Principles

Filtration is a critical component of the belt filter press process. It involves the separation of solids from liquids through a porous medium, typically a filter cloth or belt. The effectiveness of this process depends on several factors, including the properties of the material being filtered and the design of the filtration system.

Capillary Action and Porosity

The filter belt’s porosity and the capillary action within its pores play a significant role in the initial stages of filtration. Capillary action allows the liquid to penetrate the filter, while the porosity determines the rate at which the liquid passes through. A balance between these factors is crucial for optimal performance.

Pressure Differential Effects

A pressure differential across the filter belt is necessary to drive the liquid through the filter, leaving the solids behind. This pressure difference is a key factor in achieving efficient dewatering. The pressure differential enhances the filtration rate, ensuring that the process is both effective and efficient.

Mechanical Pressure and Dewatering

In addition to filtration principles, mechanical pressure plays a vital role in the dewatering process. The belt filter press applies mechanical pressure to the sludge or slurry, further reducing its moisture content. This combination of filtration and mechanical pressure enables the belt filter press to achieve high levels of dewatering efficiency.

The effectiveness of dewatering depends on the effective pressure applied and the pressing time. By optimizing these parameters, operators can significantly improve the performance of the belt filter press.

Belt Filter Press Working Principle Explained

A belt filter press achieves effective sludge dewatering by guiding the sludge through different processing zones. This multi-stage process is crucial for optimizing the dewatering efficiency and producing a drier sludge cake.

Gravity Drainage Zone

The process begins in the Gravity Drainage Zone, where the sludge is first introduced onto the filter belt. Here, free water is allowed to drain off by gravity, reducing the sludge’s moisture content. This initial stage is critical as it prepares the sludge for further dewatering by decreasing its volume and increasing its solids concentration.

Wedge Zone Compression

Following gravity drainage, the sludge enters the Wedge Zone Compression area. In this zone, the sludge is compressed between two filter belts, which gradually converge, applying gentle pressure. This compression helps to remove more water from the sludge, further increasing its solids content.

High-Pressure Shear Zone

The final stage occurs in the High-Pressure Shear Zone, where the sludge is subjected to high pressure and shear forces as it passes through a series of rollers. This intense pressure and the shear forces generated by the movement of the belts effectively remove a significant amount of the remaining water, resulting in a drier sludge cake.

| Processing Zone | Function | Effect on Sludge |

|---|---|---|

| Gravity Drainage Zone | Initial water removal by gravity | Reduces moisture content |

| Wedge Zone Compression | Compression between converging belts | Increases solids concentration |

| High-Pressure Shear Zone | High pressure and shear forces applied | Produces a drier sludge cake |

The belt filter press working principle is designed to maximize dewatering efficiency through these distinct stages, making it a valuable technology in various industries.

Key Components of a Belt Filter Press

Understanding the key components of a belt filter press is crucial for optimizing its performance. A belt filter press is made up of several critical parts that work together to achieve efficient dewatering.

Filter Belts and Materials

The filter belts are a crucial component, responsible for the separation of liquids and solids. These belts are typically made from wear-resistant materials to withstand the rigors of the filtration process.

Synthetic vs. Natural Fibers

Filter belts can be made from either synthetic or natural fibers. Synthetic fibers, such as polyester or polyamide, offer high durability and resistance to chemicals, while natural fibers may be used in specific applications where biodegradability is a concern.

Mesh Sizes and Applications

The mesh size of the filter belts varies depending on the application. Finer meshes are used for smaller particle sizes, while coarser meshes are suitable for larger particles. The choice of mesh size directly affects the efficiency of the filtration process.

| Mesh Size | Application | Particle Size |

|---|---|---|

| Fine | Municipal wastewater | Small |

| Medium | Industrial wastewater | Medium |

| Coarse | Mining | Large |

Rollers and Tensioning Systems

Rollers play a vital role in guiding and tensioning the filter belts. The tensioning system ensures that the belts remain taut, preventing slippage and maintaining optimal filtration pressure.

Drive Mechanisms and Control Systems

The drive mechanisms and control systems are responsible for the smooth operation of the belt filter press. Modern systems often include advanced controls that allow for precise adjustment of operational parameters, enhancing efficiency and reducing maintenance needs.

In conclusion, the key components of a belt filter press work together to achieve efficient dewatering. Understanding these components is essential for optimizing the performance of the equipment.

The Complete Belt Filter Press Process

Understanding the complete belt filter press process is essential for optimizing its performance in various industrial applications. The process involves several key stages that work together to achieve efficient solid-liquid separation.

Sludge Conditioning and Chemical Treatment

Sludge conditioning is a critical step that prepares the sludge for dewatering. This involves the use of chemicals to alter the sludge’s properties, making it more amenable to filtration.

Flocculants and Coagulants

Flocculants and coagulants play a vital role in sludge conditioning. Flocculants help aggregate particles into larger clumps, while coagulants neutralize charges, facilitating the formation of these clumps.

Optimal Dosing Strategies

Determining the optimal dosage of flocculants and coagulants is crucial. Overdosing can lead to wasted chemicals and potential operational issues, while underdosing may result in inadequate conditioning.

Feeding and Distribution Systems

The feeding system is responsible for delivering the conditioned sludge onto the belt filter press. Efficient distribution ensures uniform application across the belt, which is critical for effective dewatering.

Filtration and Dewatering Stages

The belt filter press operates through several dewatering stages, including gravity drainage, wedge zone compression, and high-pressure shear zone dewatering. As stated by industry experts, “The combination of these stages allows for the efficient removal of water from the sludge, resulting in a dry cake.”

“The belt filter press is a highly effective tool for sludge dewatering, offering a robust solution for various industrial needs.”

The entire process is designed to maximize dewatering efficiency, producing a dry cake that is easier to handle and dispose of.

Types of Belt Filter Presses and Configurations

Industrial belt filter presses come in multiple configurations, each with its own advantages. The design of these systems is crucial for efficient dewatering and treatment of various sludge types.

Single Belt Systems

Single belt systems are designed for simpler applications where the sludge characteristics are relatively consistent. These systems are often less expensive to install and maintain. However, they may not be as effective for complex or variable sludge types.

Double Belt Systems

Double belt systems are more versatile and can handle a wider range of sludge types. They offer improved dewatering efficiency due to the additional belt, which provides extra compression and shear force. This results in drier cake and potentially lower disposal costs.

Multi-Belt and Specialized Configurations

Multi-belt and specialized configurations are designed for challenging applications or specific industry needs. These advanced systems can offer enhanced performance, flexibility, and customization. They are particularly useful in industries with complex wastewater treatment requirements.

The choice of belt filter press configuration depends on factors such as sludge type, desired dryness, and specific industry requirements. Understanding the different types and configurations is essential for selecting the most appropriate system for efficient and effective dewatering.

Applications Across Different Industries

From wastewater treatment to industrial processing, belt filter presses play a crucial role in numerous applications. Their versatility and efficiency make them a preferred choice for solid-liquid separation in various sectors.

Municipal Wastewater Treatment

In municipal wastewater treatment, belt filter presses are utilized for sludge dewatering, significantly reducing the volume of waste and making it easier to handle and dispose of. The continuous belt filter press operation ensures a high throughput and efficient dewatering process.

Mining and Mineral Processing

The mining and mineral processing industries rely on belt filter presses for the separation of valuable minerals from waste materials. The robust design and operation of these presses enable them to handle abrasive materials effectively.

Food, Beverage, and Paper Industries

In the food, beverage, and paper industries, belt filter presses are used for product recovery and waste minimization. They help in recovering valuable products from process streams and reducing waste disposal costs.

The diverse applications of belt filter presses underscore their importance in modern industrial processes. With their ability to efficiently separate liquids from solids, they contribute significantly to the operational efficiency and environmental sustainability of various industries.

Optimizing Belt Filter Press Performance

To achieve maximum efficiency, understanding how to optimize a belt filter press is essential. Optimizing performance involves adjusting operational parameters to enhance the dewatering process.

Key Operational Parameters

Several key operational parameters play a crucial role in the performance of a belt filter press. These include belt speed and tension, as well as feed rate and consistency.

Belt Speed and Tension

The belt speed and tension are critical factors that influence the efficiency of the dewatering process. Proper adjustment of these parameters ensures optimal performance.

Feed Rate and Consistency

The feed rate and consistency of the sludge or slurry being processed also significantly impact the belt filter press’s performance. Maintaining a consistent feed rate is vital for achieving uniform dewatering.

Efficiency Factors and Measurement

Measuring the efficiency of a belt filter press involves assessing various factors, including the dryness of the cake produced and the clarity of the filtrate. Efficient operation is characterized by high cake dryness and clear filtrate.

“The efficiency of a belt filter press is directly related to its ability to produce a dry cake and clear filtrate.”

| Efficiency Factor | Description | Impact on Performance |

|---|---|---|

| Cake Dryness | Percentage of dry solids in the cake | Higher dryness indicates better efficiency |

| Filtrate Clarity | Clarity of the liquid separated from the solids | Clearer filtrate suggests more effective separation |

Troubleshooting Common Issues

Common issues such as belt misalignment, incorrect tension, and uneven feed distribution can significantly affect the performance of a belt filter press. Regular maintenance and monitoring are essential for troubleshooting these issues.

By understanding and adjusting the key operational parameters, measuring efficiency factors, and troubleshooting common issues, operators can significantly enhance the performance of their belt filter press.

Comparing Belt Filter Presses to Other Dewatering Technologies

Dewatering is a critical process in many industries, and selecting the right equipment is crucial for efficiency and cost-effectiveness. The choice of dewatering technology can significantly impact the overall performance and cost of operations.

Centrifuges vs. Belt Filter Presses

Centrifuges and belt filter presses are both used for dewatering, but they operate on different principles. Centrifuges use centrifugal force to separate liquids from solids, while belt filter presses use a combination of gravity and mechanical pressure. Belt filter presses are often preferred for their simplicity and lower energy consumption.

Filter Presses vs. Belt Filter Presses

Filter presses and belt filter presses both use mechanical pressure for dewatering, but they differ in design and operation. Filter presses are batch processes, whereas belt filter presses operate continuously. This continuous operation makes belt filter presses more suitable for high-volume applications.

Selection Criteria for Dewatering Equipment

When selecting dewatering equipment, several factors should be considered, including the type of sludge, desired dryness, and operational costs. Understanding the specific requirements of the application is key to choosing the most appropriate technology. Factors such as maintenance needs, energy consumption, and capital costs also play a crucial role in the decision-making process.

Conclusion

The belt filter press is an efficient and versatile sludge treatment equipment with a wide range of applications across various industries, including municipal wastewater treatment, mining, and mineral processing.

Understanding the belt filter press working principle is crucial for effective sludge treatment, as it enables operators to optimize the performance of the equipment and achieve desired outcomes.

A continuous belt filter press offers a reliable and efficient solution for dewatering sludge, and its working principle is based on a combination of gravity drainage, wedge zone compression, and high-pressure shear zone.

By grasping the fundamental science behind solid-liquid separation and the key components of a belt filter press, operators can troubleshoot common issues and improve the overall efficiency of the equipment.

In conclusion, the belt filter press is a valuable asset in various industries, and its effective operation relies on a thorough understanding of its working principle and configuration.